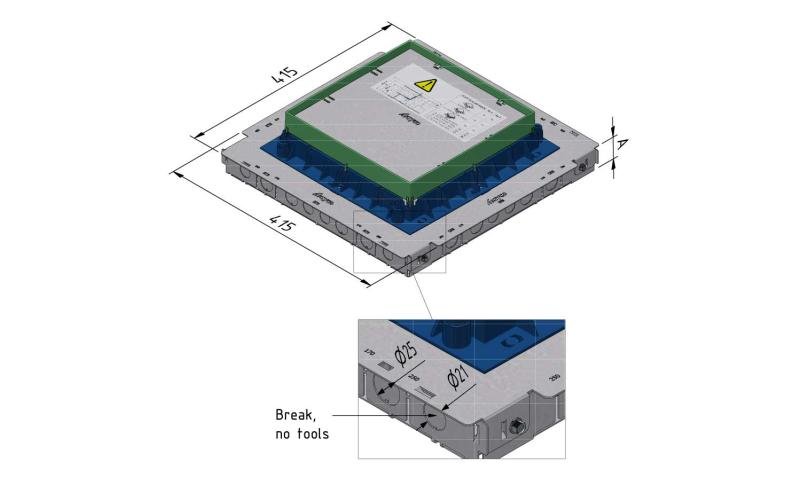

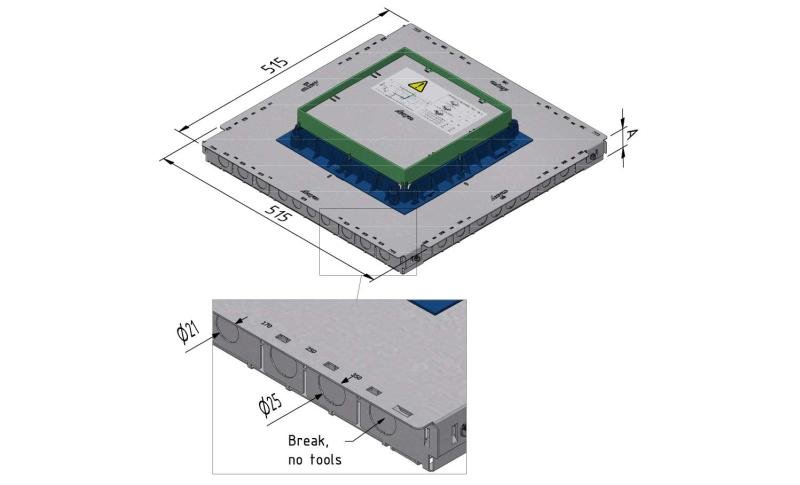

Polyconcrete

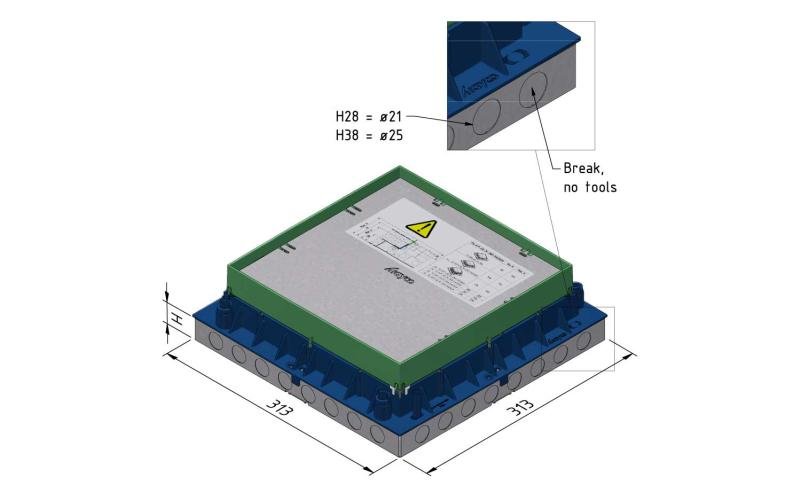

BOX-ACC-KIT-POLY

Polyconcrete

BOX-ACC-KIT-POLY

| SKU | Article code | Finishing | Packaging | |||

|---|---|---|---|---|---|---|

|

|

17188 |

FS-KIT-POLY-SQ-260-PG |

PG

|

1

|

Default

|

|

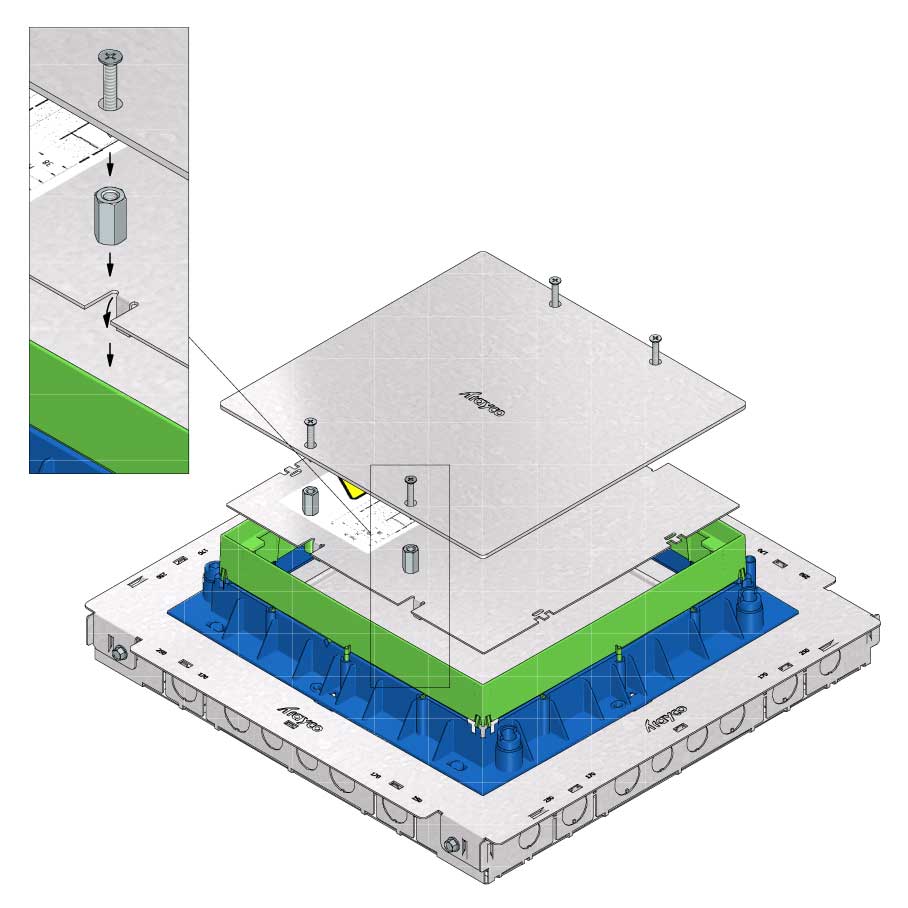

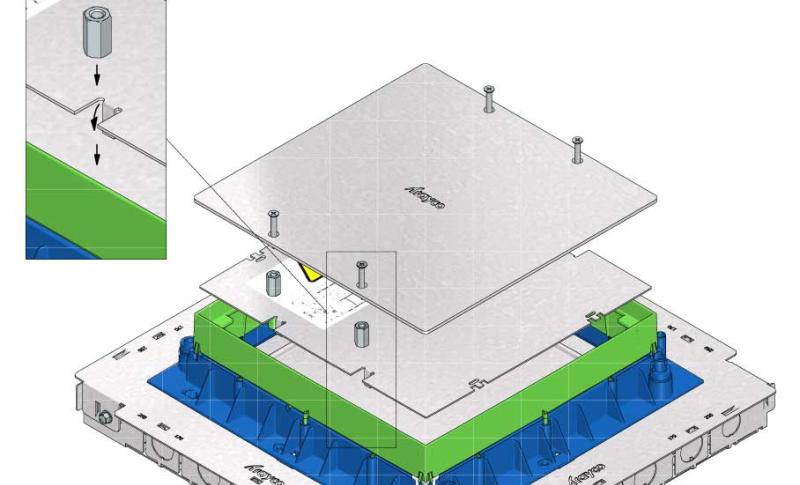

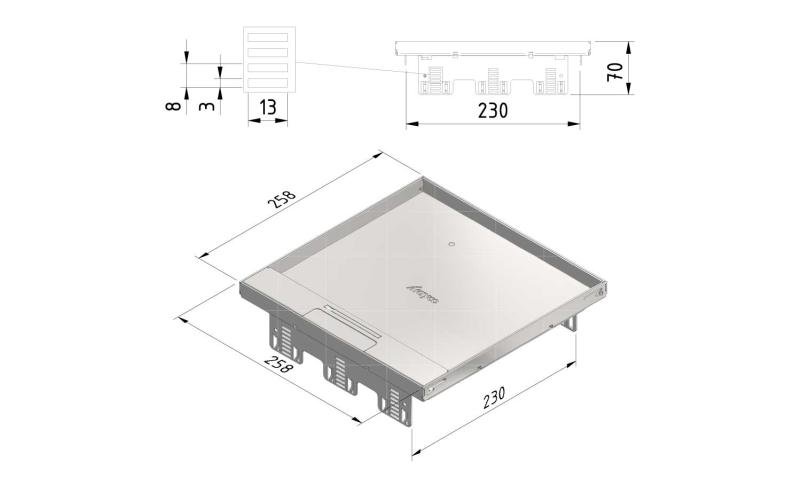

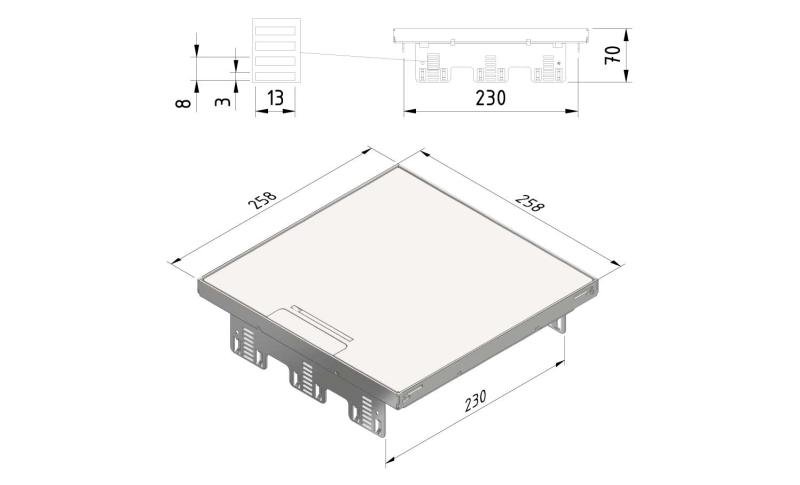

To mount the floor box in case of poly-concrete:

1) Remove the security cover from the green frame and bend the 4 lips to the downside.

2) Put the security cover in the green frame again.

3) Slide the 4 connecting nuts in the cut-outs of the security cover, where you’ve bent the lips.

4) Place the poly-concrete plate in the green frame, so that the 4 cut-outs are exactly above the connecting nuts.

5) Fix the pieces together on the green frame, using the 4 screws included in the kit.

6) After the poly-concrete is in place, remove the poly-concrete kit and the security cover from the green frame.

7) Fix the service unit directly into the green frame.