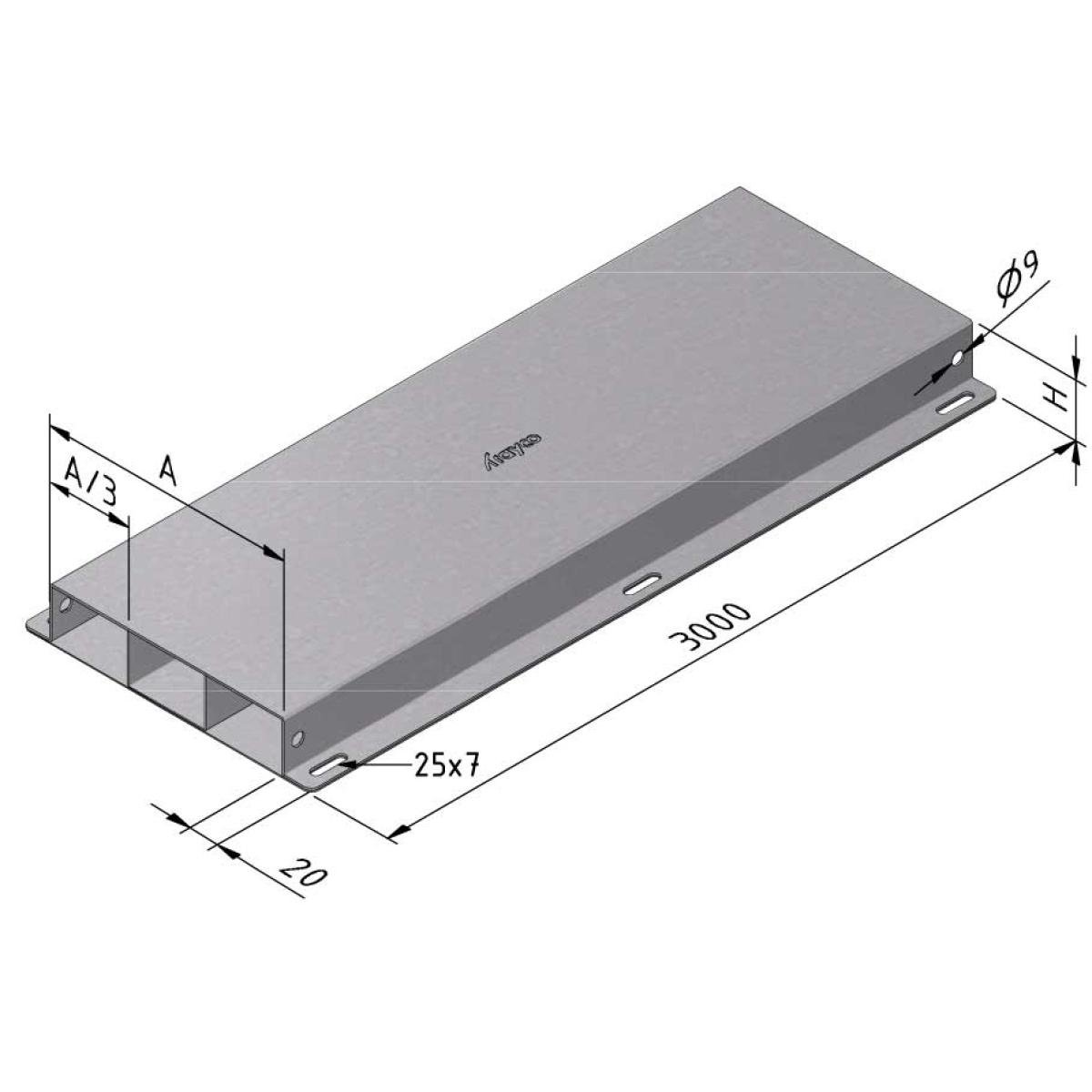

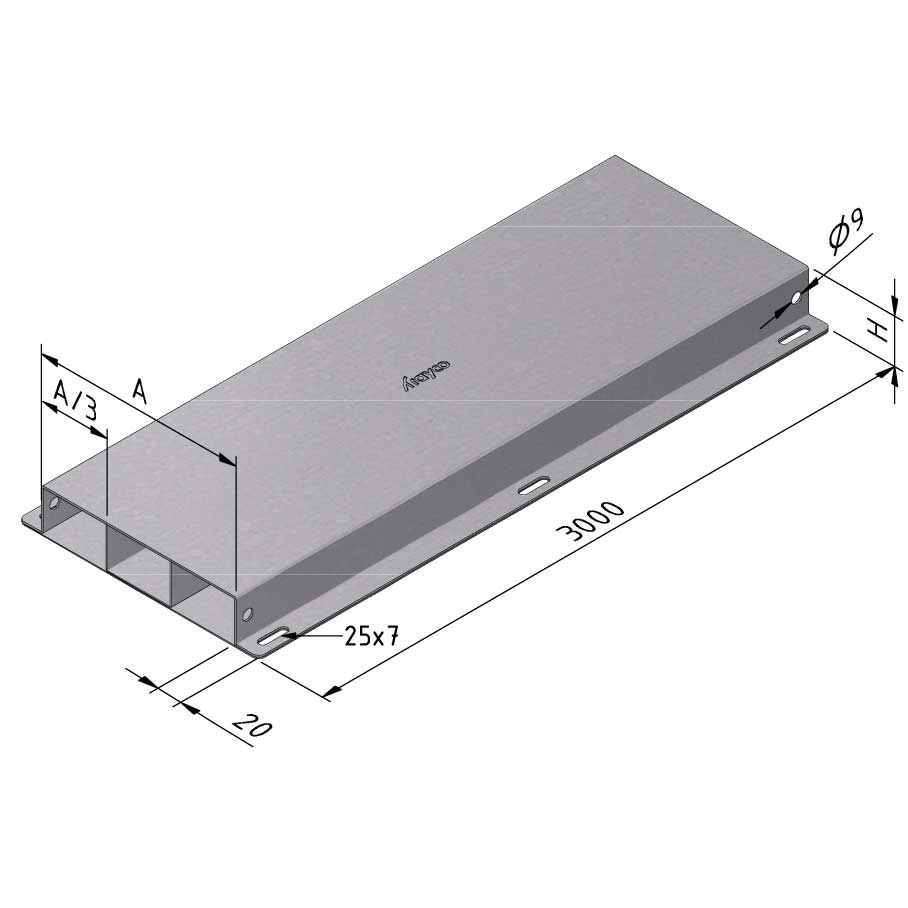

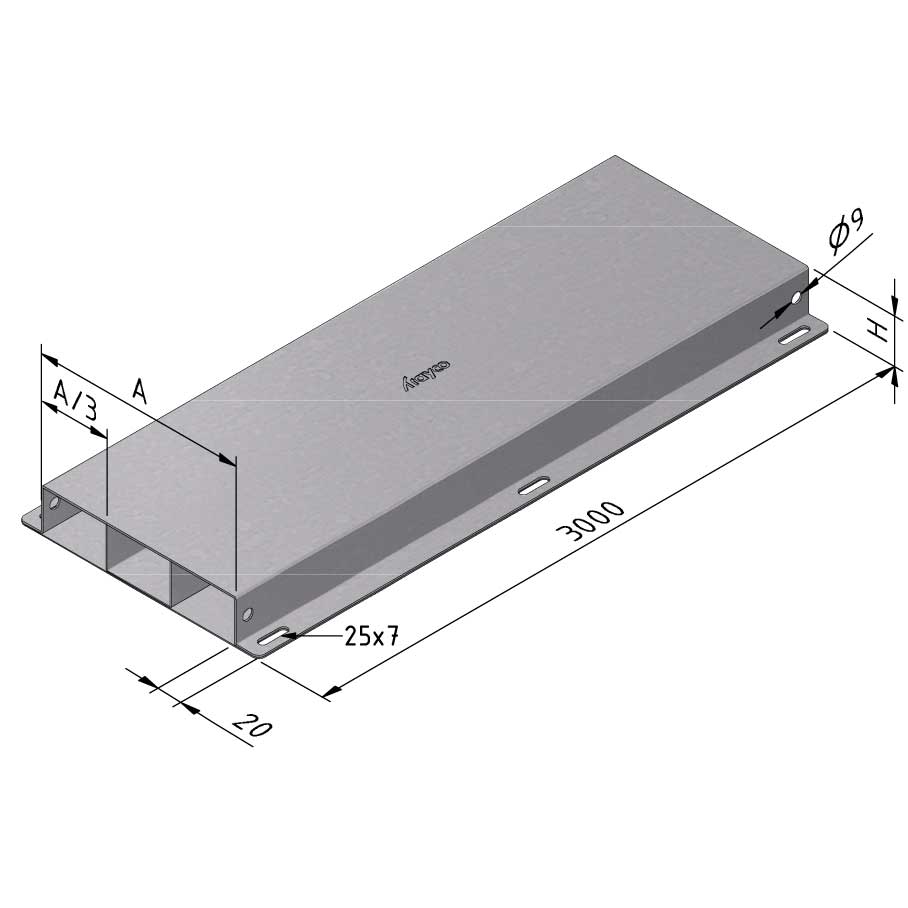

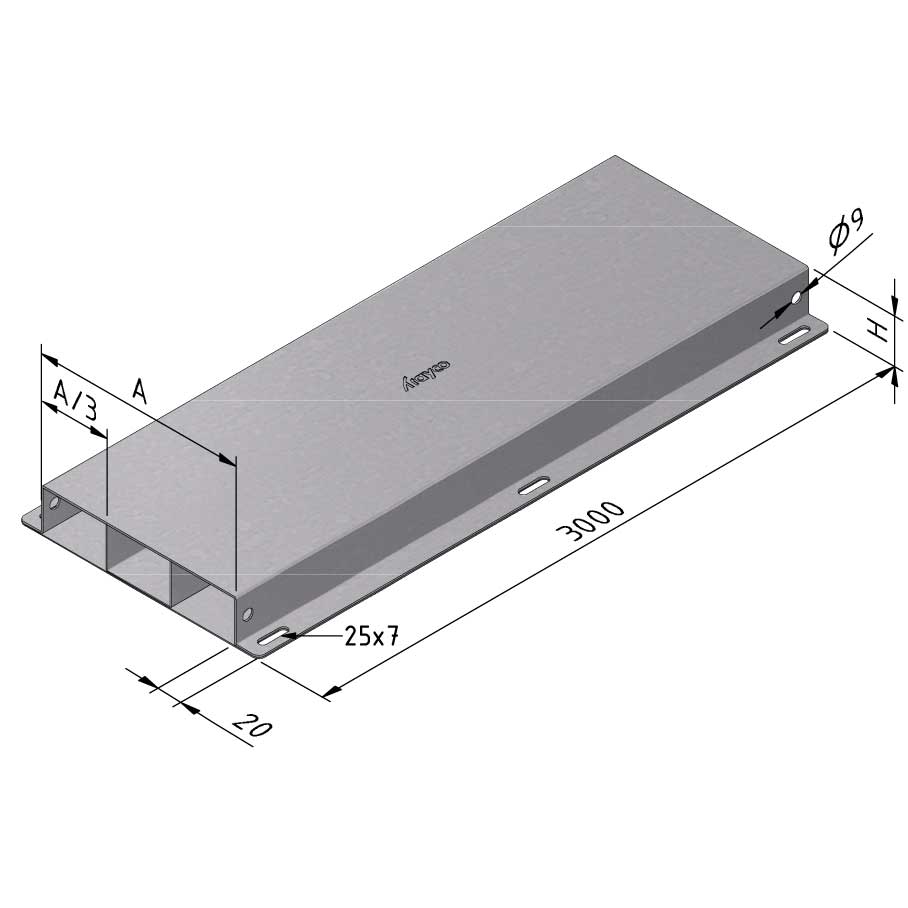

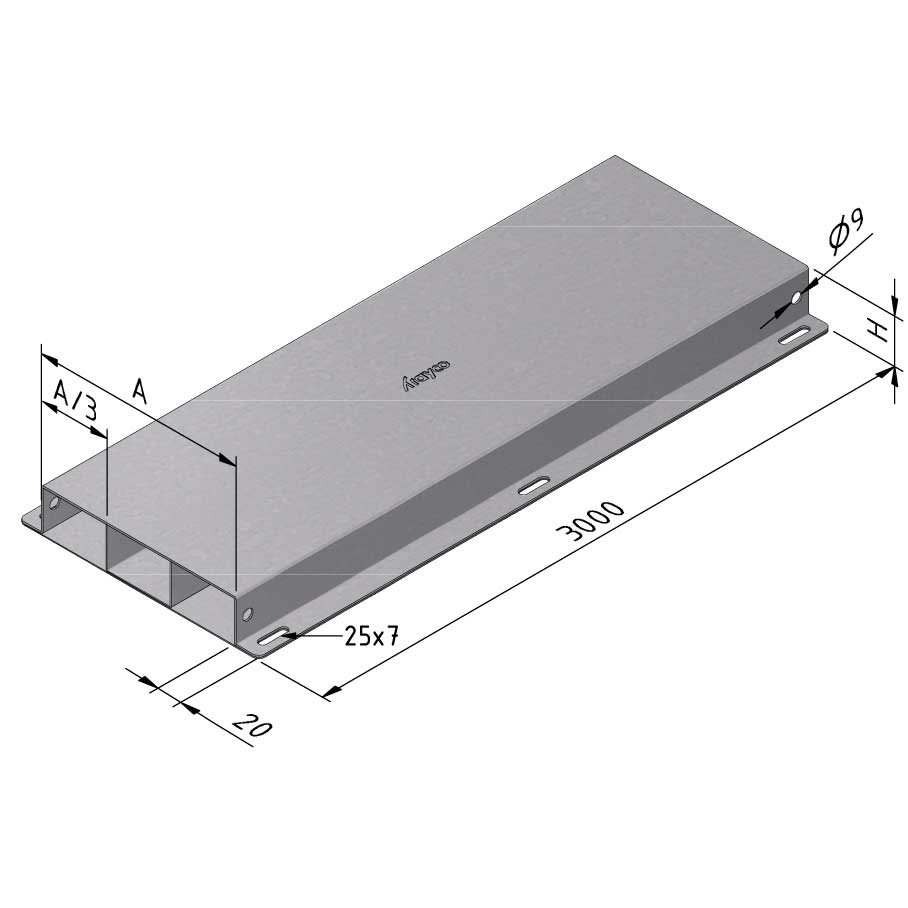

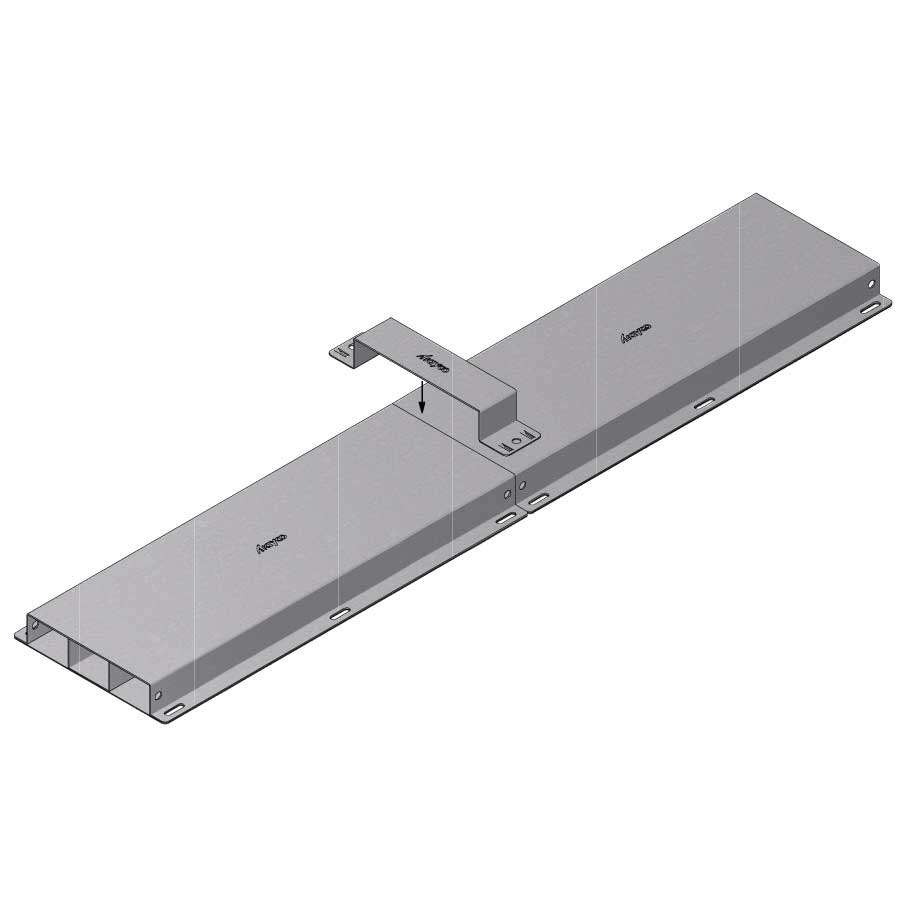

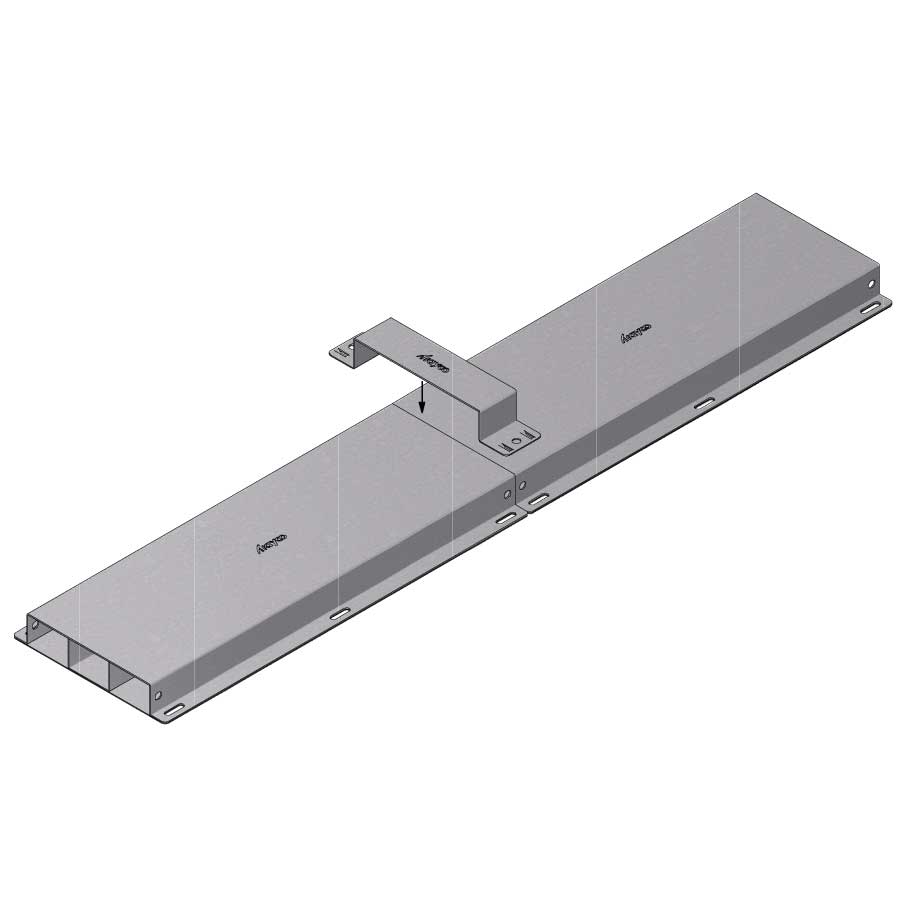

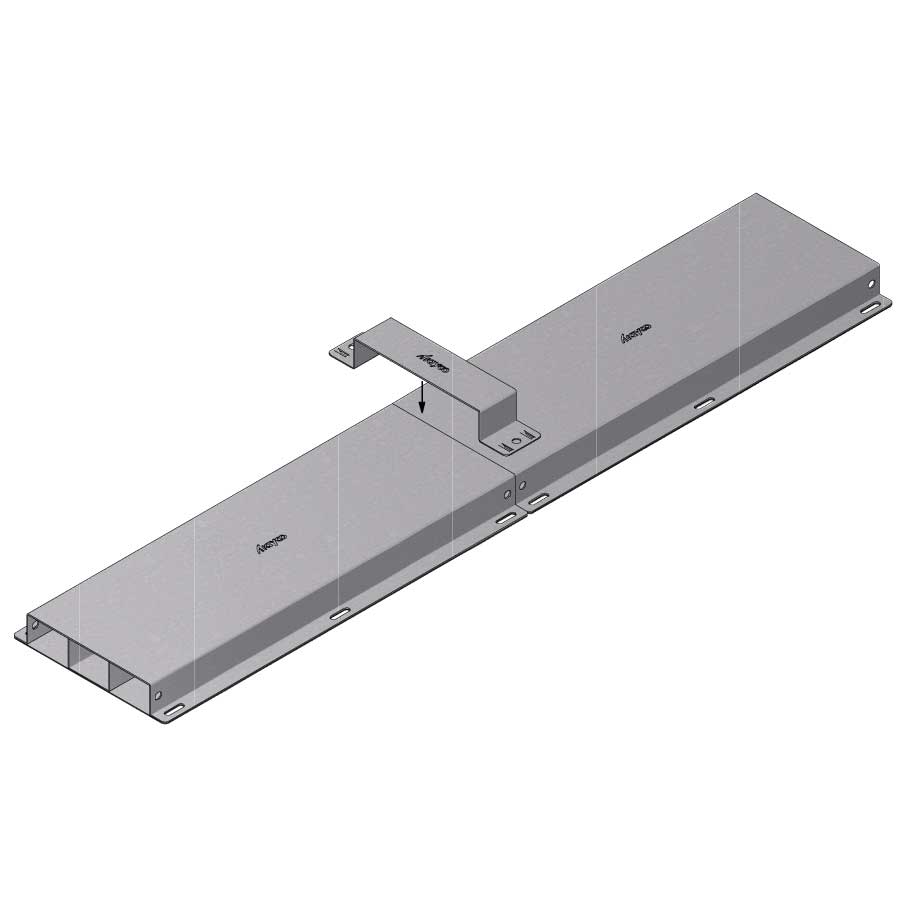

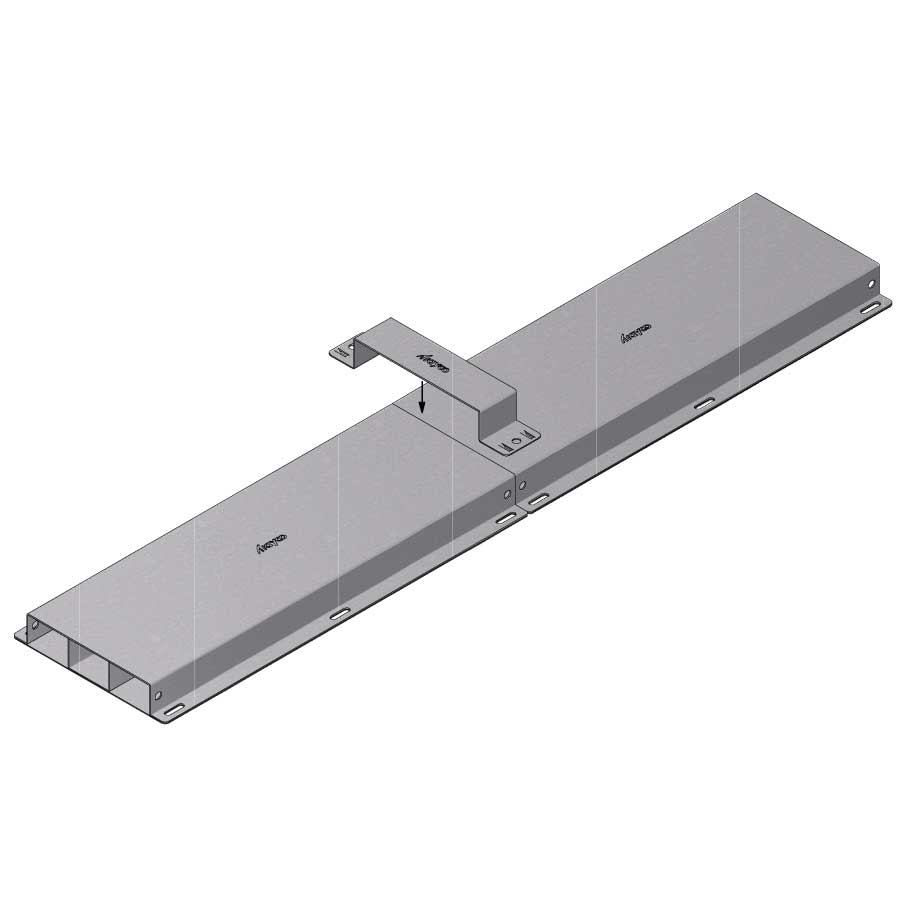

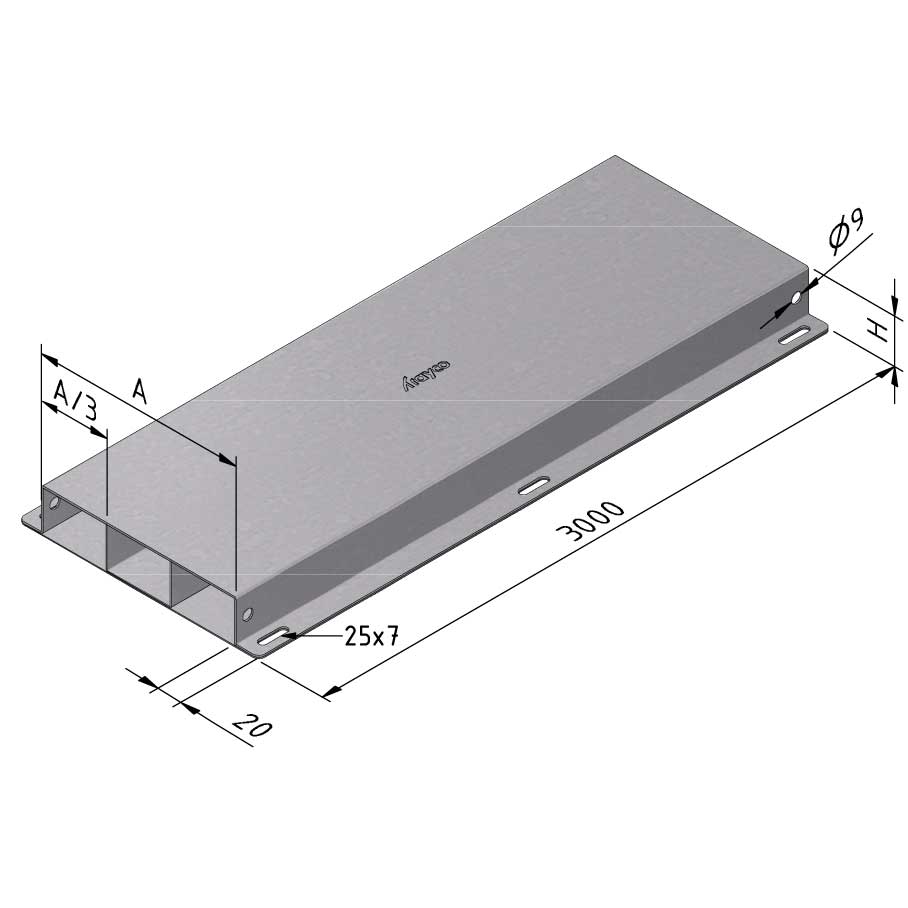

Floor duct 3 comp.

FD-3C

Floor duct 3 comp.

FD-3C

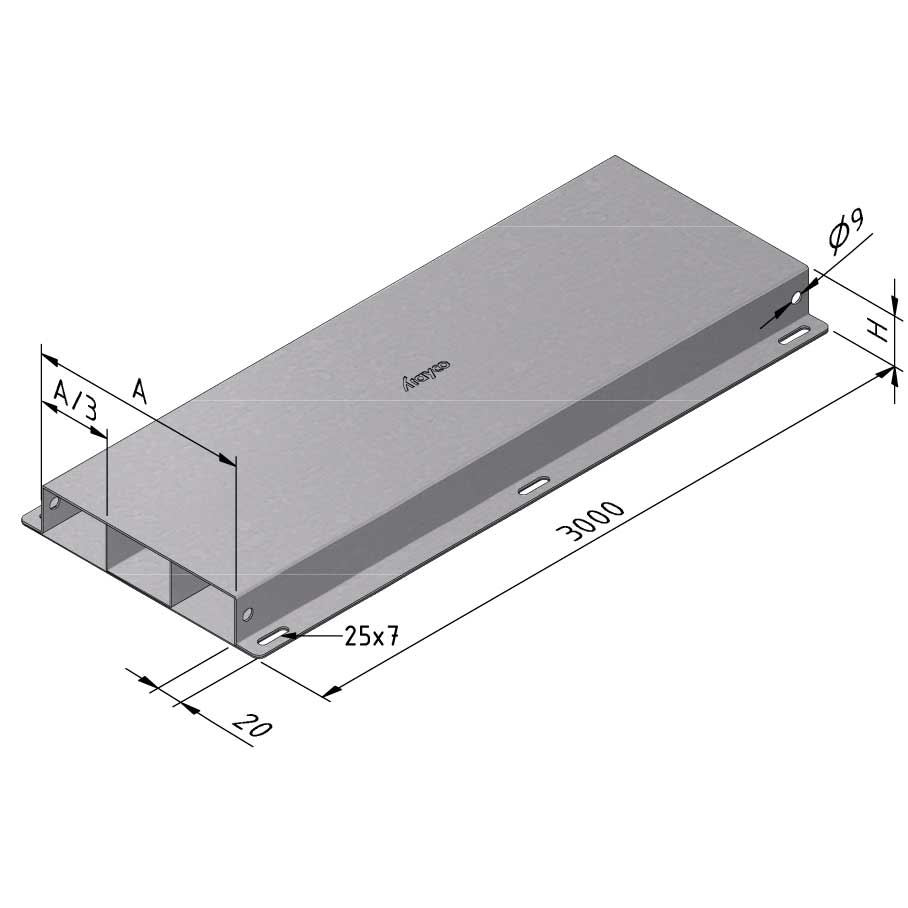

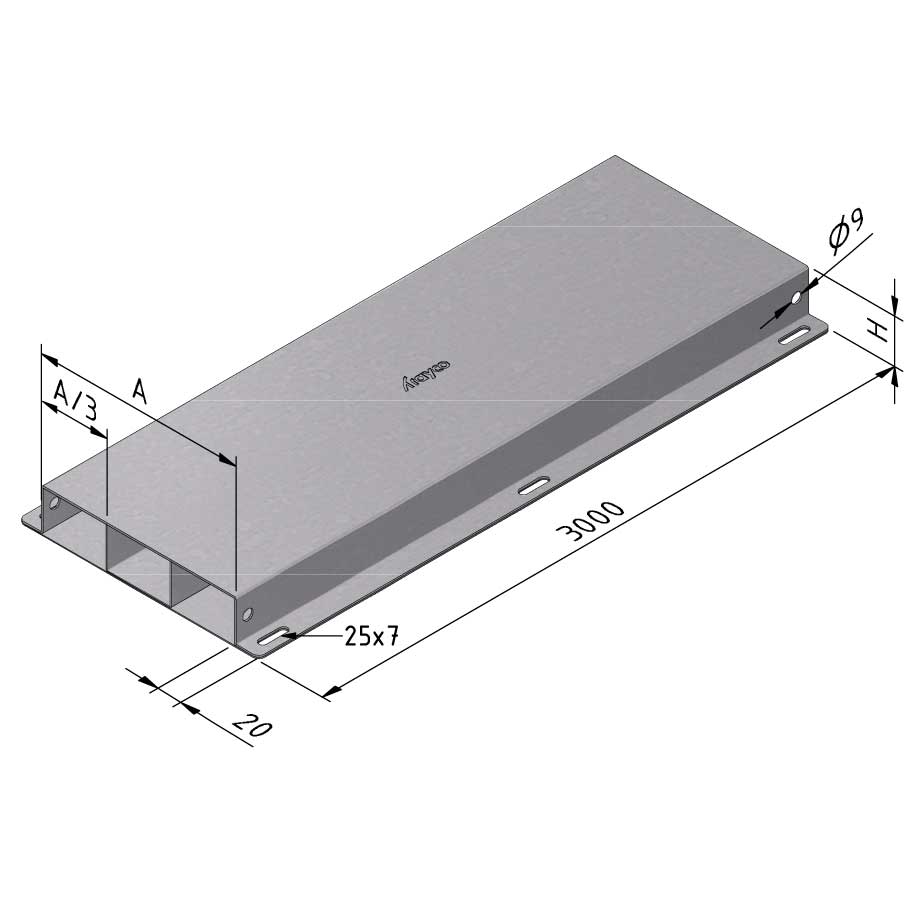

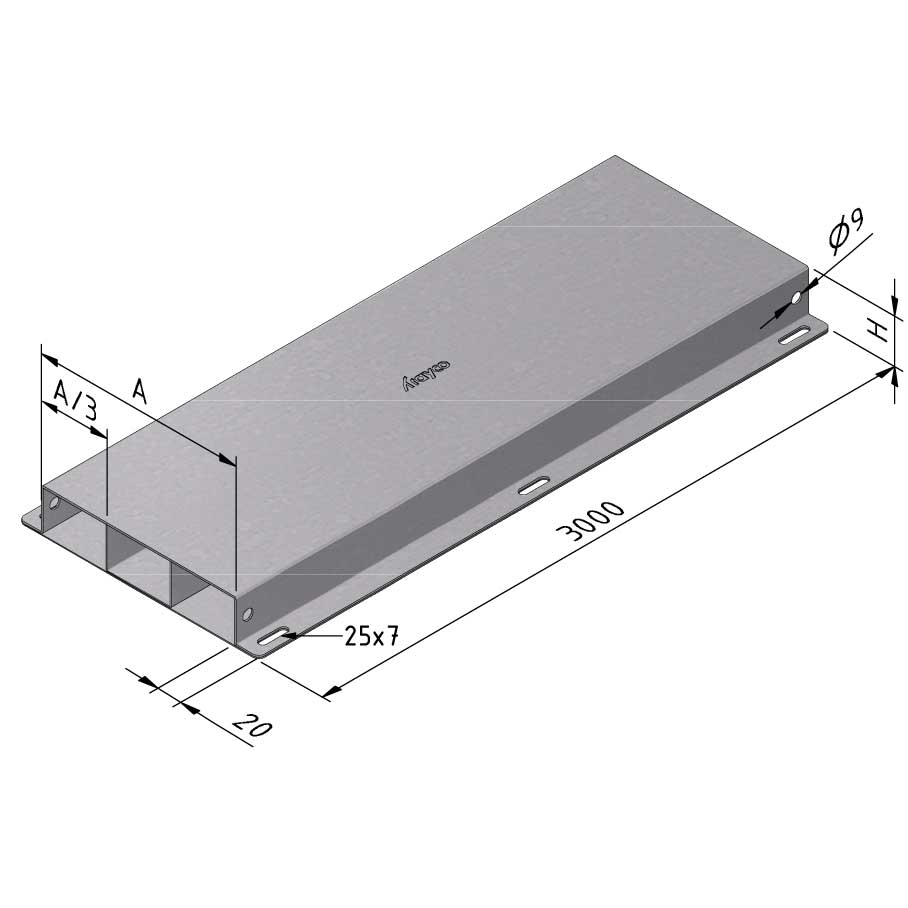

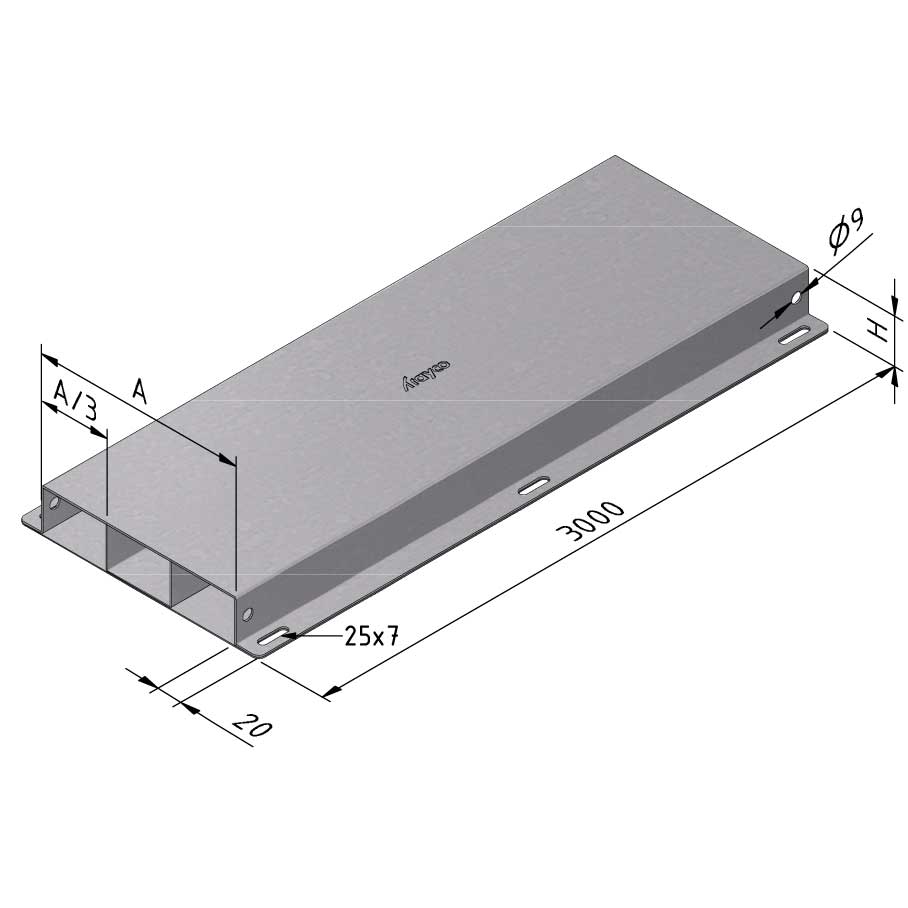

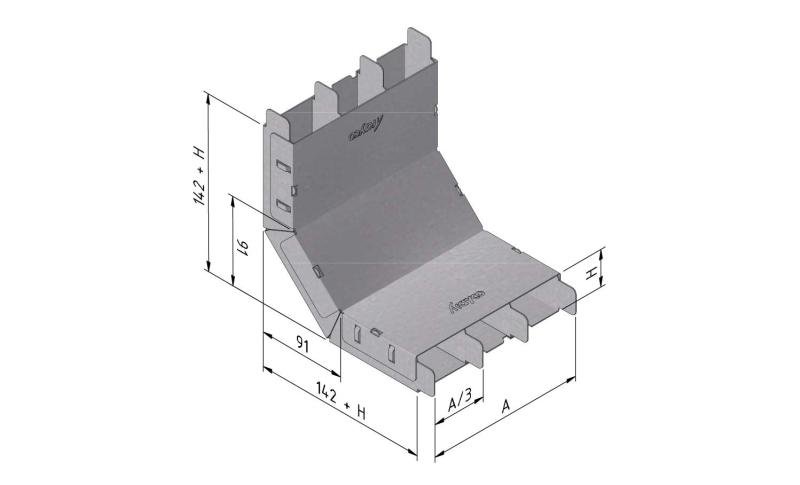

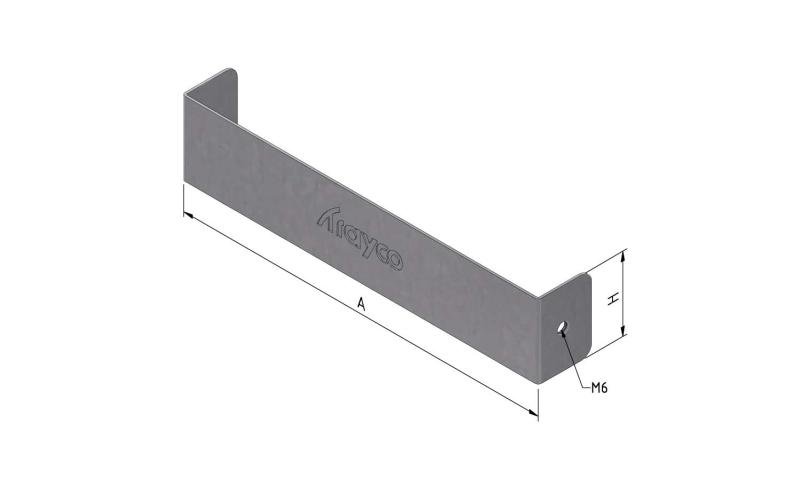

With 3 compartments (1/3 - 1/3 - 1/3)

Cover thickness: 1,5mm

Base plate thickness: 1mm

Heights: 28 - 38 - 48mm

Widths: 170 - 250 - 350mm

| SKU | Article code | Finishing | Dimension A | Usable surface (cm²) | Packaging | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

15598 |

FS-FD28-170-3C-3PG |

PG

|

170

|

43.29

|

3

|

Default

|

|

|||

Workload

Additional information

Finishing

Sendzimir galvanized (EN 10143) PG (pre-galvanized):

Products made of Sendzimir (pre-galvanized) or continuous hot-dip galvanized steel sheet and coils are mostly used wherever limited chemical contamination is likely, for example, in of ces, industrial buildings, covered parking lots, etc. Characteristic of this steel type is that – prior to mechanical deformation – it is given a zinc coating by means of a continuous dipping process. This zinc coating is easily deformed. A cathodic action occurs on cut surfaces (up to 1.5mm) that protects against oxidation. First, the steel is chemical cleaned and roughened in order to achieve a good bond. After the dipping process, the surplus zinc is blown off and one obtains an extra passivating coat (an ultra-thin protective coat) to prevent oxidation of the zinc coating (white rust). The coating thickness is usually expressed in g/m2. The most deployed type of Sendzimir steel is Z 275 = 275g/m2 (weighed on both sides), this corresponds to 18-20 µm (micron). Sendzimir galvanized steel sourced from modern galvanizing lines has, in general, a uniform, shiny appearance. The previous, common fl owery surface is scarcely seen these days. This effect is obtained under the infl uence of lead but has no eff ect on the quality of the coating. The use of lead was banned due to the ever more stringent environmental standards. |

|||||||||||

|

|

15599 |

FS-FD28-250-3C-3PG |

PG

|

250

|

64.1

|

3

|

Default

|

|

|||

Workload

Additional information

Finishing

Sendzimir galvanized (EN 10143) PG (pre-galvanized):

Products made of Sendzimir (pre-galvanized) or continuous hot-dip galvanized steel sheet and coils are mostly used wherever limited chemical contamination is likely, for example, in of ces, industrial buildings, covered parking lots, etc. Characteristic of this steel type is that – prior to mechanical deformation – it is given a zinc coating by means of a continuous dipping process. This zinc coating is easily deformed. A cathodic action occurs on cut surfaces (up to 1.5mm) that protects against oxidation. First, the steel is chemical cleaned and roughened in order to achieve a good bond. After the dipping process, the surplus zinc is blown off and one obtains an extra passivating coat (an ultra-thin protective coat) to prevent oxidation of the zinc coating (white rust). The coating thickness is usually expressed in g/m2. The most deployed type of Sendzimir steel is Z 275 = 275g/m2 (weighed on both sides), this corresponds to 18-20 µm (micron). Sendzimir galvanized steel sourced from modern galvanizing lines has, in general, a uniform, shiny appearance. The previous, common fl owery surface is scarcely seen these days. This effect is obtained under the infl uence of lead but has no eff ect on the quality of the coating. The use of lead was banned due to the ever more stringent environmental standards. |

|||||||||||

|

|

15600 |

FS-FD28-350-3C-3PG |

PG

|

350

|

90.09

|

3

|

Default

|

|

|||

Workload

Additional information

Finishing

Sendzimir galvanized (EN 10143) PG (pre-galvanized):

Products made of Sendzimir (pre-galvanized) or continuous hot-dip galvanized steel sheet and coils are mostly used wherever limited chemical contamination is likely, for example, in of ces, industrial buildings, covered parking lots, etc. Characteristic of this steel type is that – prior to mechanical deformation – it is given a zinc coating by means of a continuous dipping process. This zinc coating is easily deformed. A cathodic action occurs on cut surfaces (up to 1.5mm) that protects against oxidation. First, the steel is chemical cleaned and roughened in order to achieve a good bond. After the dipping process, the surplus zinc is blown off and one obtains an extra passivating coat (an ultra-thin protective coat) to prevent oxidation of the zinc coating (white rust). The coating thickness is usually expressed in g/m2. The most deployed type of Sendzimir steel is Z 275 = 275g/m2 (weighed on both sides), this corresponds to 18-20 µm (micron). Sendzimir galvanized steel sourced from modern galvanizing lines has, in general, a uniform, shiny appearance. The previous, common fl owery surface is scarcely seen these days. This effect is obtained under the infl uence of lead but has no eff ect on the quality of the coating. The use of lead was banned due to the ever more stringent environmental standards. |

|||||||||||

|

|

15604 |

FS-FD38-170-3C-3PG |

PG

|

170

|

59.94

|

3

|

Default

|

|

|||

Workload

Additional information

Finishing

Sendzimir galvanized (EN 10143) PG (pre-galvanized):

Products made of Sendzimir (pre-galvanized) or continuous hot-dip galvanized steel sheet and coils are mostly used wherever limited chemical contamination is likely, for example, in of ces, industrial buildings, covered parking lots, etc. Characteristic of this steel type is that – prior to mechanical deformation – it is given a zinc coating by means of a continuous dipping process. This zinc coating is easily deformed. A cathodic action occurs on cut surfaces (up to 1.5mm) that protects against oxidation. First, the steel is chemical cleaned and roughened in order to achieve a good bond. After the dipping process, the surplus zinc is blown off and one obtains an extra passivating coat (an ultra-thin protective coat) to prevent oxidation of the zinc coating (white rust). The coating thickness is usually expressed in g/m2. The most deployed type of Sendzimir steel is Z 275 = 275g/m2 (weighed on both sides), this corresponds to 18-20 µm (micron). Sendzimir galvanized steel sourced from modern galvanizing lines has, in general, a uniform, shiny appearance. The previous, common fl owery surface is scarcely seen these days. This effect is obtained under the infl uence of lead but has no eff ect on the quality of the coating. The use of lead was banned due to the ever more stringent environmental standards. |

|||||||||||

|

|

15605 |

FS-FD38-250-3C-3PG |

PG

|

250

|

88.75

|

3

|

Default

|

|

|||

Workload

Additional information

Finishing

Sendzimir galvanized (EN 10143) PG (pre-galvanized):

Products made of Sendzimir (pre-galvanized) or continuous hot-dip galvanized steel sheet and coils are mostly used wherever limited chemical contamination is likely, for example, in of ces, industrial buildings, covered parking lots, etc. Characteristic of this steel type is that – prior to mechanical deformation – it is given a zinc coating by means of a continuous dipping process. This zinc coating is easily deformed. A cathodic action occurs on cut surfaces (up to 1.5mm) that protects against oxidation. First, the steel is chemical cleaned and roughened in order to achieve a good bond. After the dipping process, the surplus zinc is blown off and one obtains an extra passivating coat (an ultra-thin protective coat) to prevent oxidation of the zinc coating (white rust). The coating thickness is usually expressed in g/m2. The most deployed type of Sendzimir steel is Z 275 = 275g/m2 (weighed on both sides), this corresponds to 18-20 µm (micron). Sendzimir galvanized steel sourced from modern galvanizing lines has, in general, a uniform, shiny appearance. The previous, common fl owery surface is scarcely seen these days. This effect is obtained under the infl uence of lead but has no eff ect on the quality of the coating. The use of lead was banned due to the ever more stringent environmental standards. |

|||||||||||

|

|

15606 |

FS-FD38-350-3C-3PG |

PG

|

350

|

124.74

|

3

|

Default

|

|

|||

Workload

Additional information

Finishing

Sendzimir galvanized (EN 10143) PG (pre-galvanized):

Products made of Sendzimir (pre-galvanized) or continuous hot-dip galvanized steel sheet and coils are mostly used wherever limited chemical contamination is likely, for example, in of ces, industrial buildings, covered parking lots, etc. Characteristic of this steel type is that – prior to mechanical deformation – it is given a zinc coating by means of a continuous dipping process. This zinc coating is easily deformed. A cathodic action occurs on cut surfaces (up to 1.5mm) that protects against oxidation. First, the steel is chemical cleaned and roughened in order to achieve a good bond. After the dipping process, the surplus zinc is blown off and one obtains an extra passivating coat (an ultra-thin protective coat) to prevent oxidation of the zinc coating (white rust). The coating thickness is usually expressed in g/m2. The most deployed type of Sendzimir steel is Z 275 = 275g/m2 (weighed on both sides), this corresponds to 18-20 µm (micron). Sendzimir galvanized steel sourced from modern galvanizing lines has, in general, a uniform, shiny appearance. The previous, common fl owery surface is scarcely seen these days. This effect is obtained under the infl uence of lead but has no eff ect on the quality of the coating. The use of lead was banned due to the ever more stringent environmental standards. |

|||||||||||

|

|

15610 |

FS-FD48-170-3C-3PG |

PG

|

170

|

76.59

|

3

|

Default

|

|

|||

Workload

Additional information

Finishing

Sendzimir galvanized (EN 10143) PG (pre-galvanized):

Products made of Sendzimir (pre-galvanized) or continuous hot-dip galvanized steel sheet and coils are mostly used wherever limited chemical contamination is likely, for example, in of ces, industrial buildings, covered parking lots, etc. Characteristic of this steel type is that – prior to mechanical deformation – it is given a zinc coating by means of a continuous dipping process. This zinc coating is easily deformed. A cathodic action occurs on cut surfaces (up to 1.5mm) that protects against oxidation. First, the steel is chemical cleaned and roughened in order to achieve a good bond. After the dipping process, the surplus zinc is blown off and one obtains an extra passivating coat (an ultra-thin protective coat) to prevent oxidation of the zinc coating (white rust). The coating thickness is usually expressed in g/m2. The most deployed type of Sendzimir steel is Z 275 = 275g/m2 (weighed on both sides), this corresponds to 18-20 µm (micron). Sendzimir galvanized steel sourced from modern galvanizing lines has, in general, a uniform, shiny appearance. The previous, common fl owery surface is scarcely seen these days. This effect is obtained under the infl uence of lead but has no eff ect on the quality of the coating. The use of lead was banned due to the ever more stringent environmental standards. |

|||||||||||

|

|

15611 |

FS-FD48-250-3C-3PG |

PG

|

250

|

113.39

|

3

|

Default

|

|

|||

Workload

Additional information

Finishing

Sendzimir galvanized (EN 10143) PG (pre-galvanized):

Products made of Sendzimir (pre-galvanized) or continuous hot-dip galvanized steel sheet and coils are mostly used wherever limited chemical contamination is likely, for example, in of ces, industrial buildings, covered parking lots, etc. Characteristic of this steel type is that – prior to mechanical deformation – it is given a zinc coating by means of a continuous dipping process. This zinc coating is easily deformed. A cathodic action occurs on cut surfaces (up to 1.5mm) that protects against oxidation. First, the steel is chemical cleaned and roughened in order to achieve a good bond. After the dipping process, the surplus zinc is blown off and one obtains an extra passivating coat (an ultra-thin protective coat) to prevent oxidation of the zinc coating (white rust). The coating thickness is usually expressed in g/m2. The most deployed type of Sendzimir steel is Z 275 = 275g/m2 (weighed on both sides), this corresponds to 18-20 µm (micron). Sendzimir galvanized steel sourced from modern galvanizing lines has, in general, a uniform, shiny appearance. The previous, common fl owery surface is scarcely seen these days. This effect is obtained under the infl uence of lead but has no eff ect on the quality of the coating. The use of lead was banned due to the ever more stringent environmental standards. |

|||||||||||

|

|

15612 |

FS-FD48-350-3C-3PG |

PG

|

350

|

159.39

|

3

|

Default

|

|

|||

Workload

Additional information

Finishing

Sendzimir galvanized (EN 10143) PG (pre-galvanized):

Products made of Sendzimir (pre-galvanized) or continuous hot-dip galvanized steel sheet and coils are mostly used wherever limited chemical contamination is likely, for example, in of ces, industrial buildings, covered parking lots, etc. Characteristic of this steel type is that – prior to mechanical deformation – it is given a zinc coating by means of a continuous dipping process. This zinc coating is easily deformed. A cathodic action occurs on cut surfaces (up to 1.5mm) that protects against oxidation. First, the steel is chemical cleaned and roughened in order to achieve a good bond. After the dipping process, the surplus zinc is blown off and one obtains an extra passivating coat (an ultra-thin protective coat) to prevent oxidation of the zinc coating (white rust). The coating thickness is usually expressed in g/m2. The most deployed type of Sendzimir steel is Z 275 = 275g/m2 (weighed on both sides), this corresponds to 18-20 µm (micron). Sendzimir galvanized steel sourced from modern galvanizing lines has, in general, a uniform, shiny appearance. The previous, common fl owery surface is scarcely seen these days. This effect is obtained under the infl uence of lead but has no eff ect on the quality of the coating. The use of lead was banned due to the ever more stringent environmental standards. |

|||||||||||

EN50085 compliant.

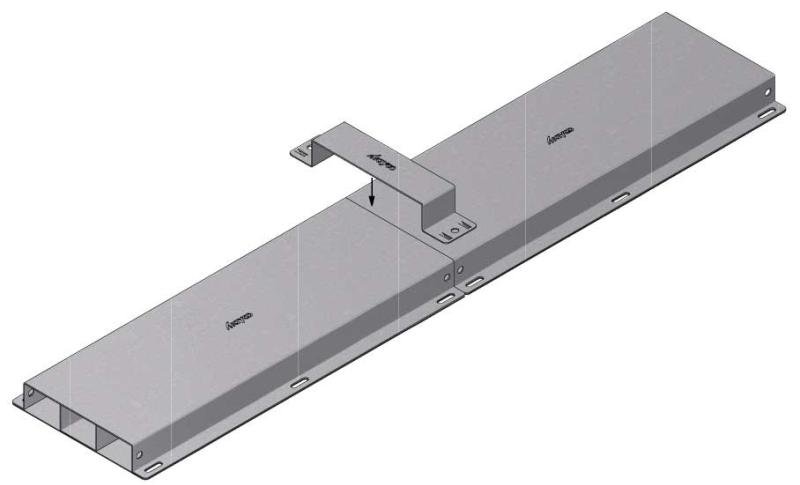

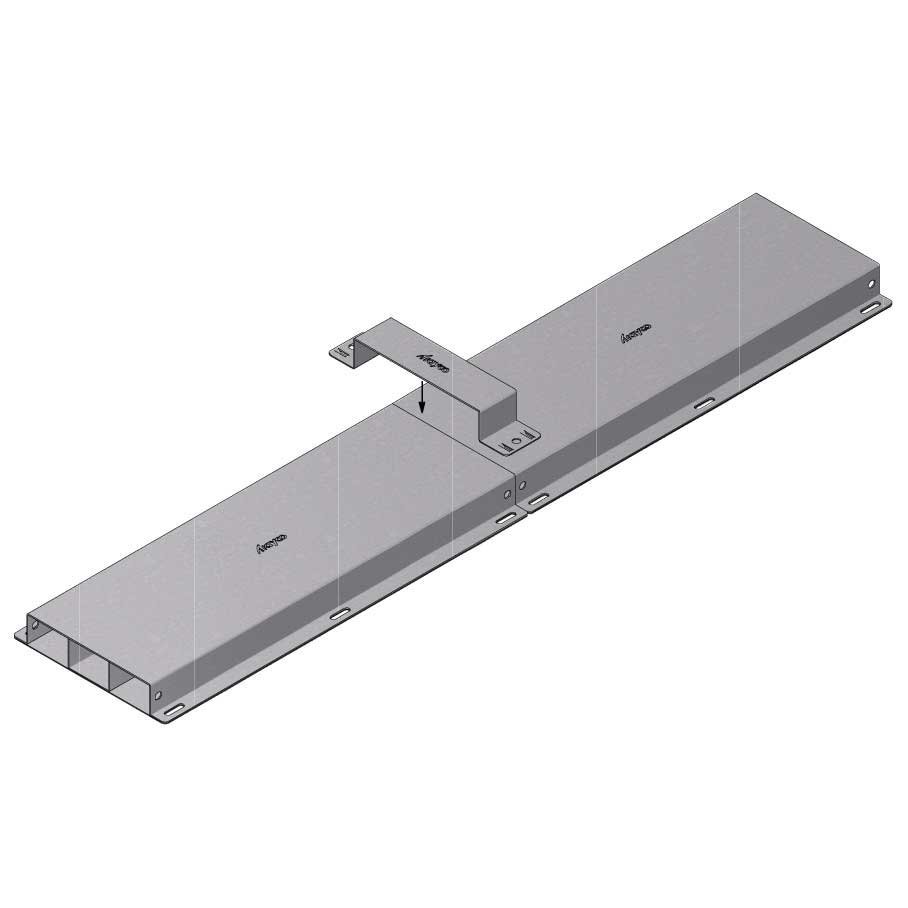

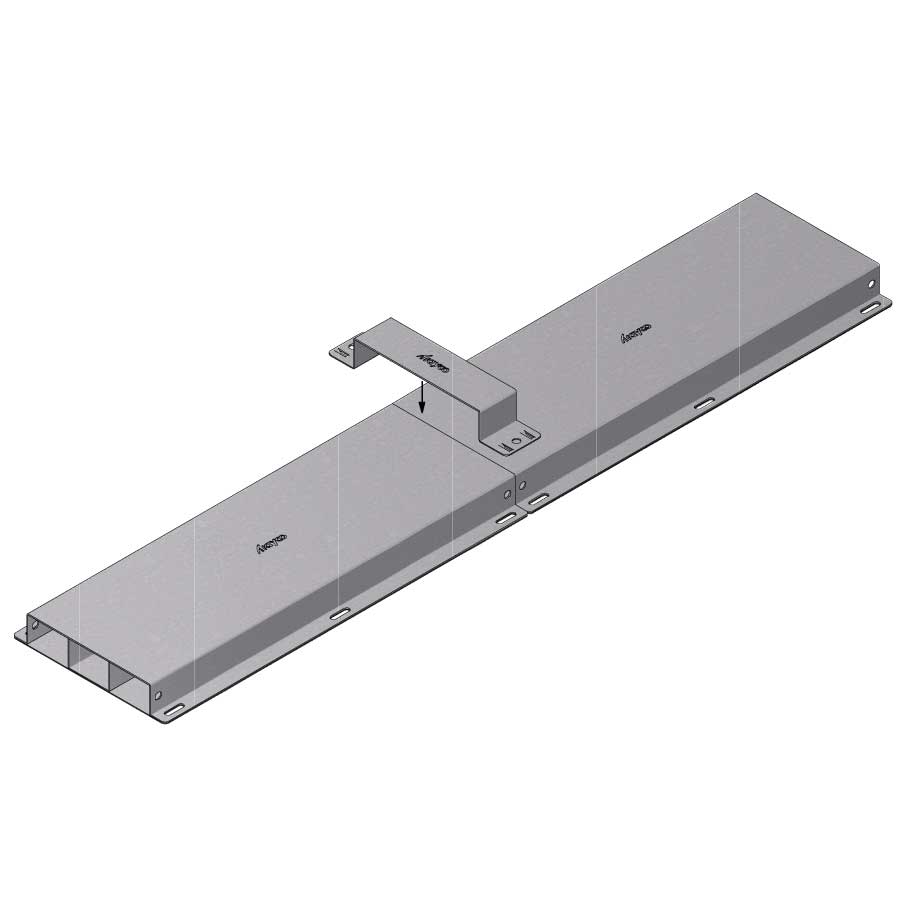

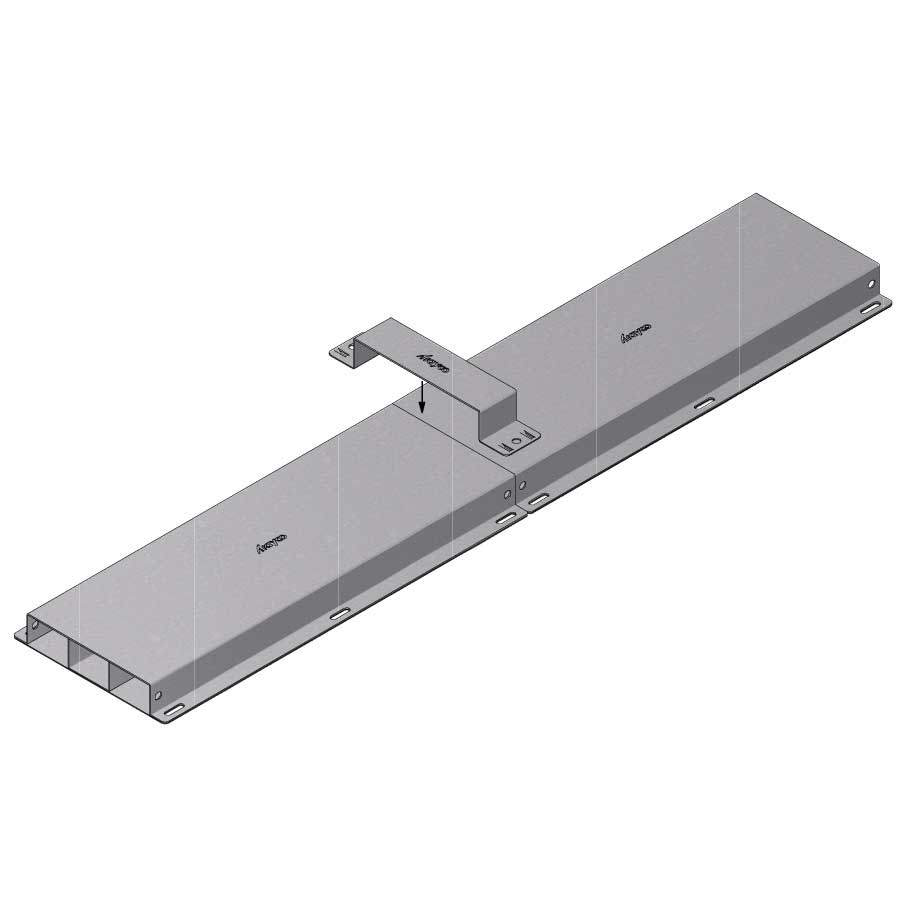

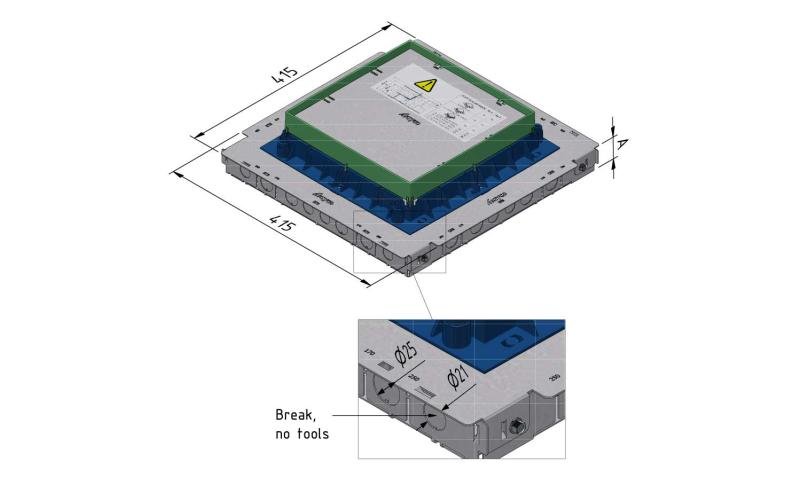

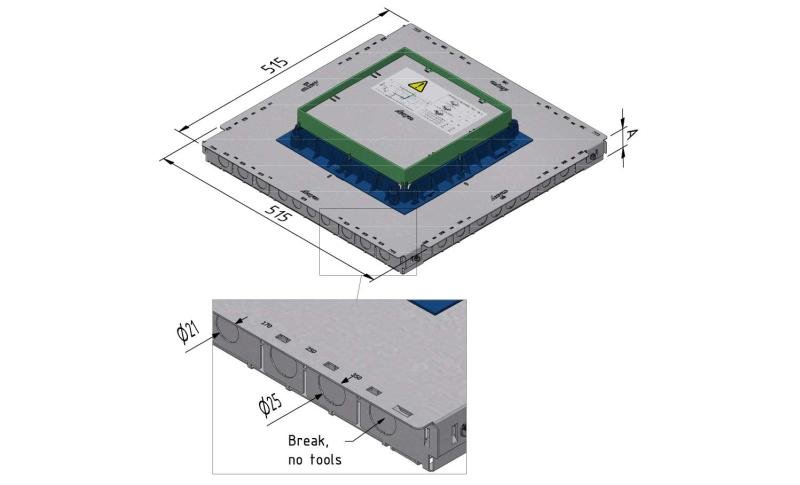

Slides into the floorbox FS-BOX.

Suitable for pulling cables.

Robust and strong.

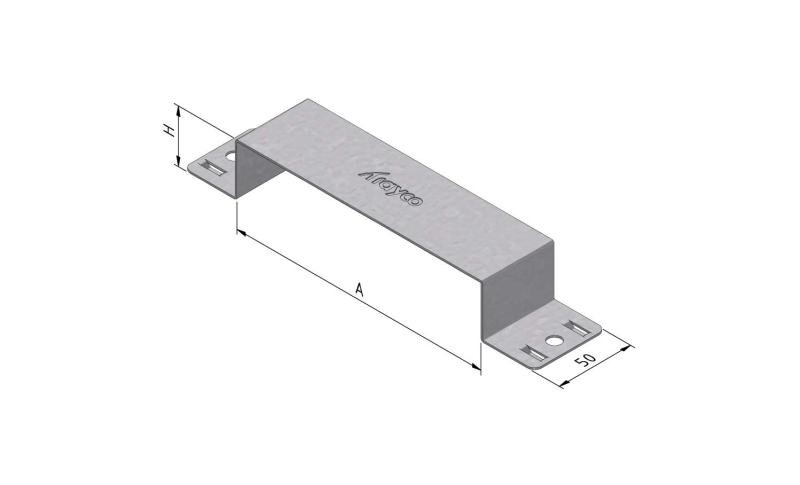

Fixation by means of FS-FD-FB.

No results

No results were found for your current search