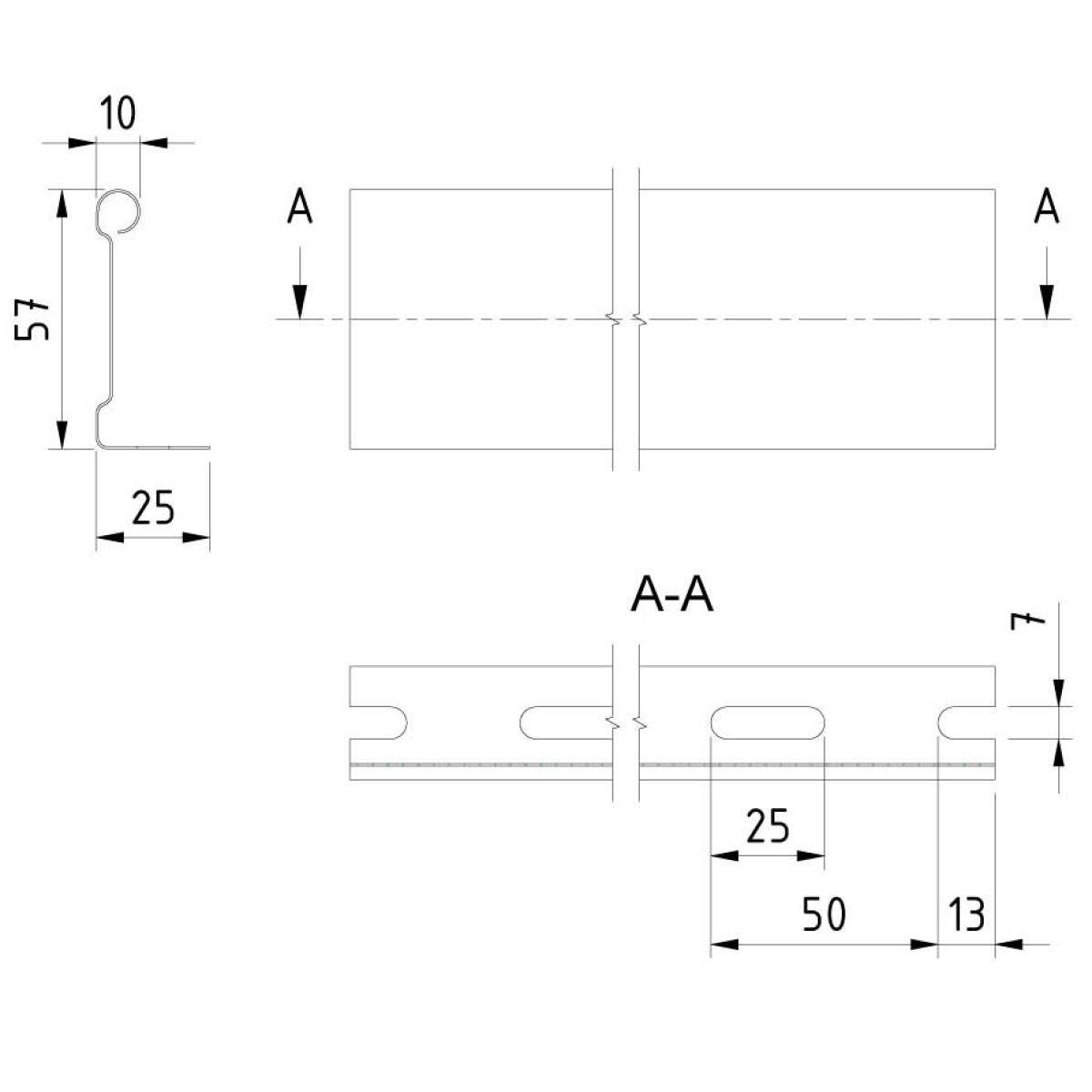

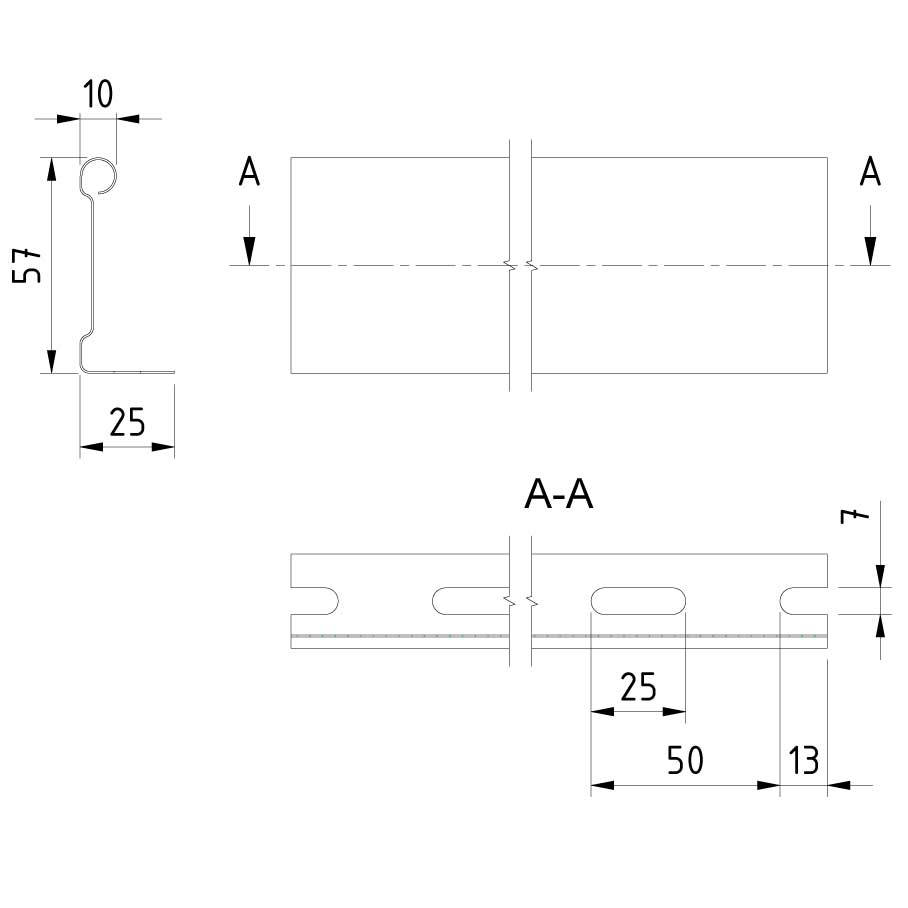

Divider cable ladder

CL-D

Divider cable ladder

CL-D

CLFI60 / CLF110: Connect with RHB06-10 + SLN30-06

CLF125 / CLF160 / CLF200:Connect with RHB06-10 + SLN41-06

Connect the dividers to each other with BN06-10

Coated finishing available on demand. RAL colour code to be confirmed on your order