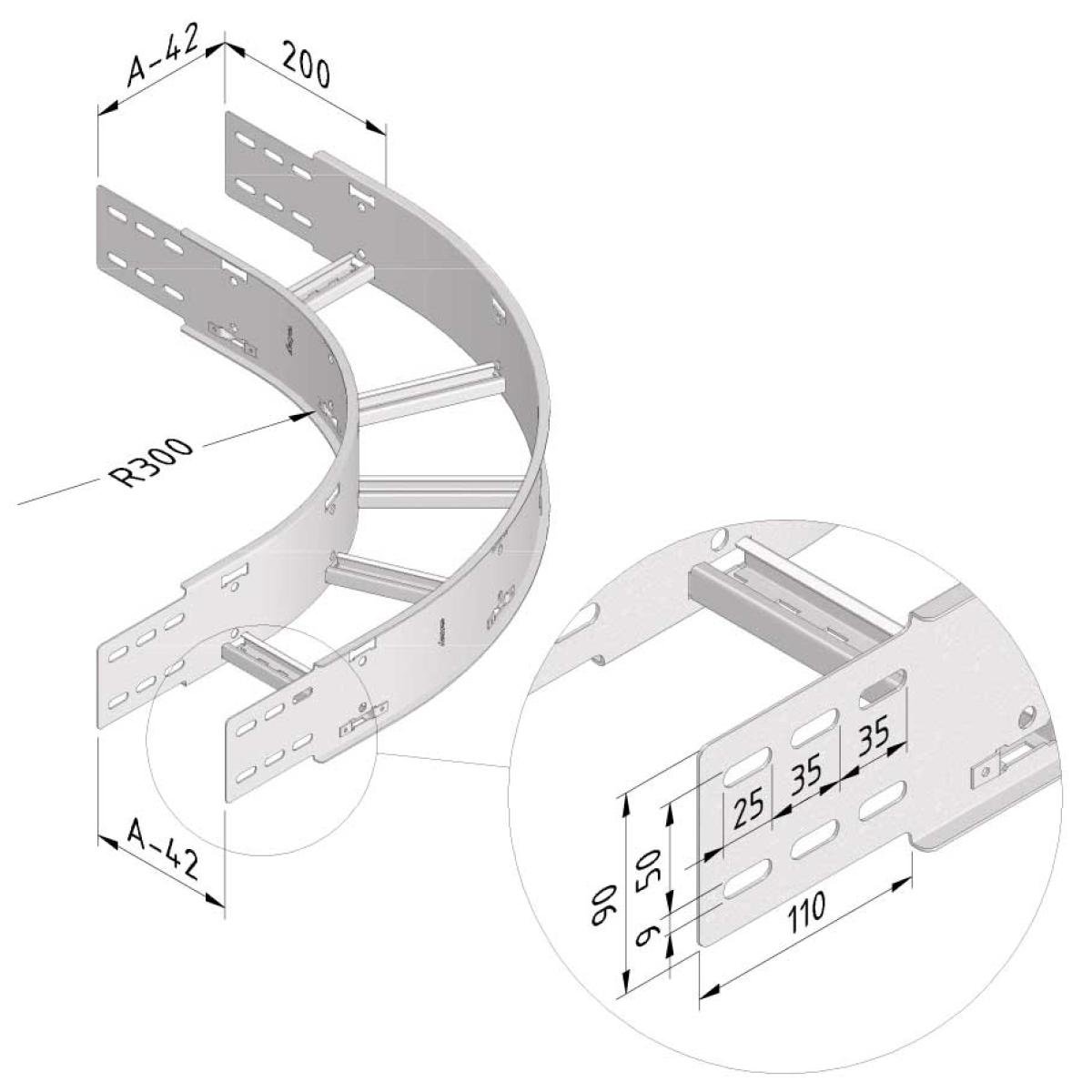

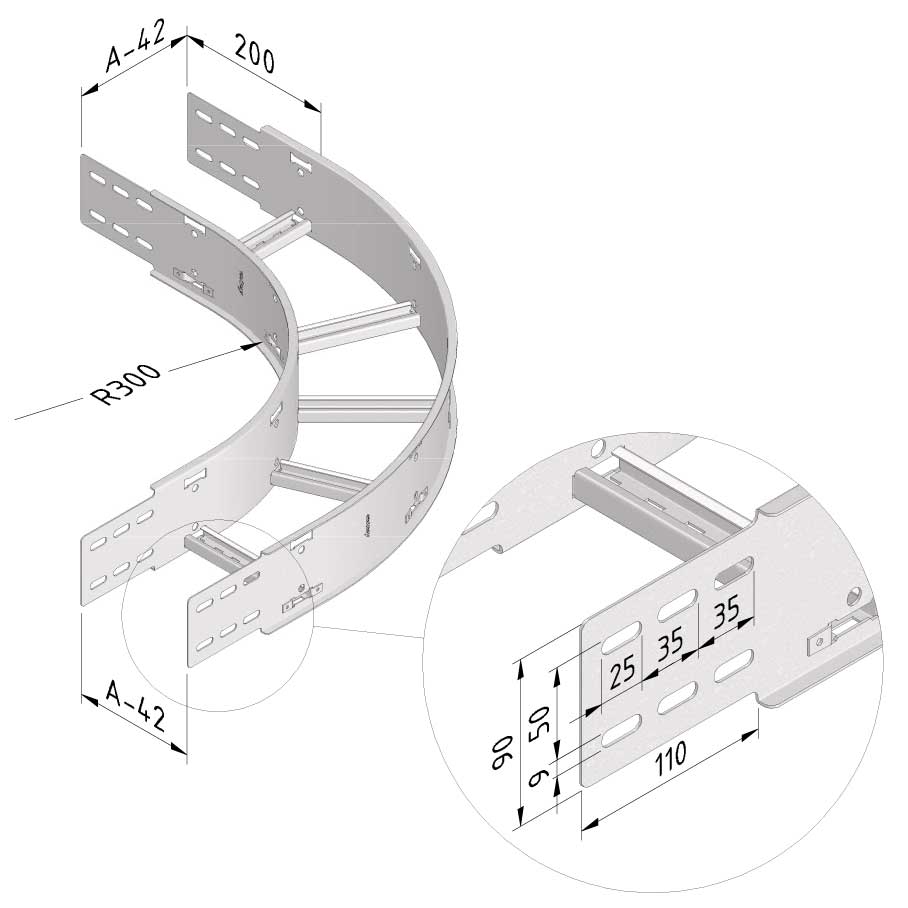

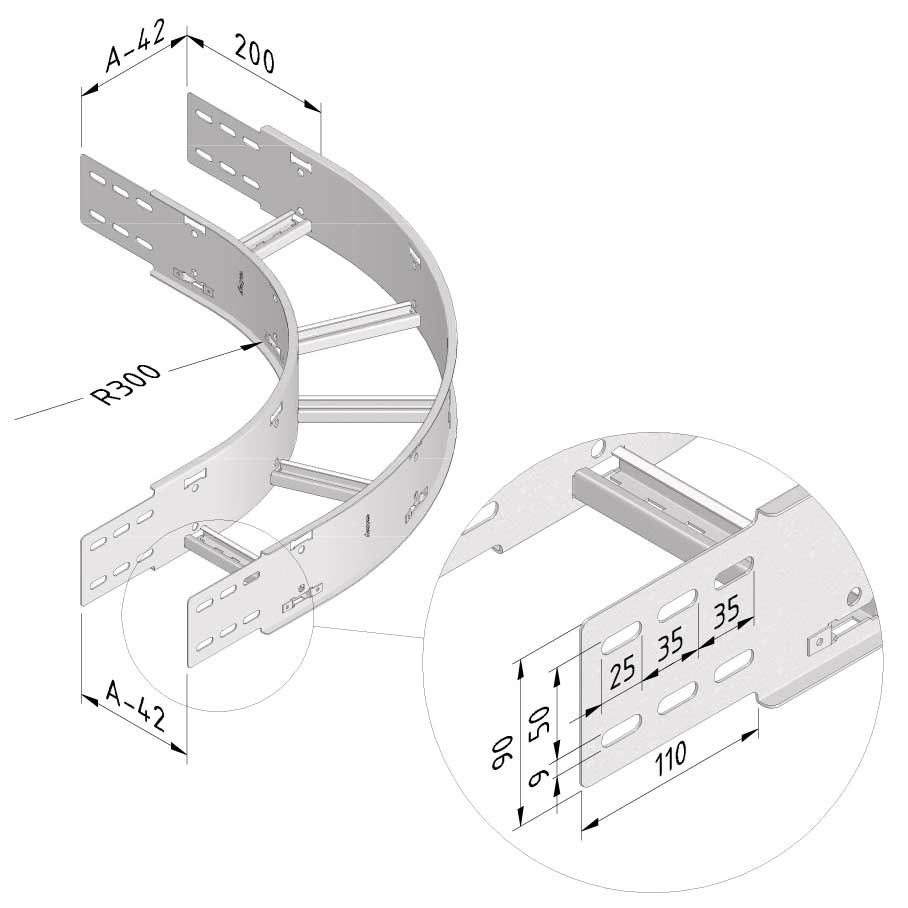

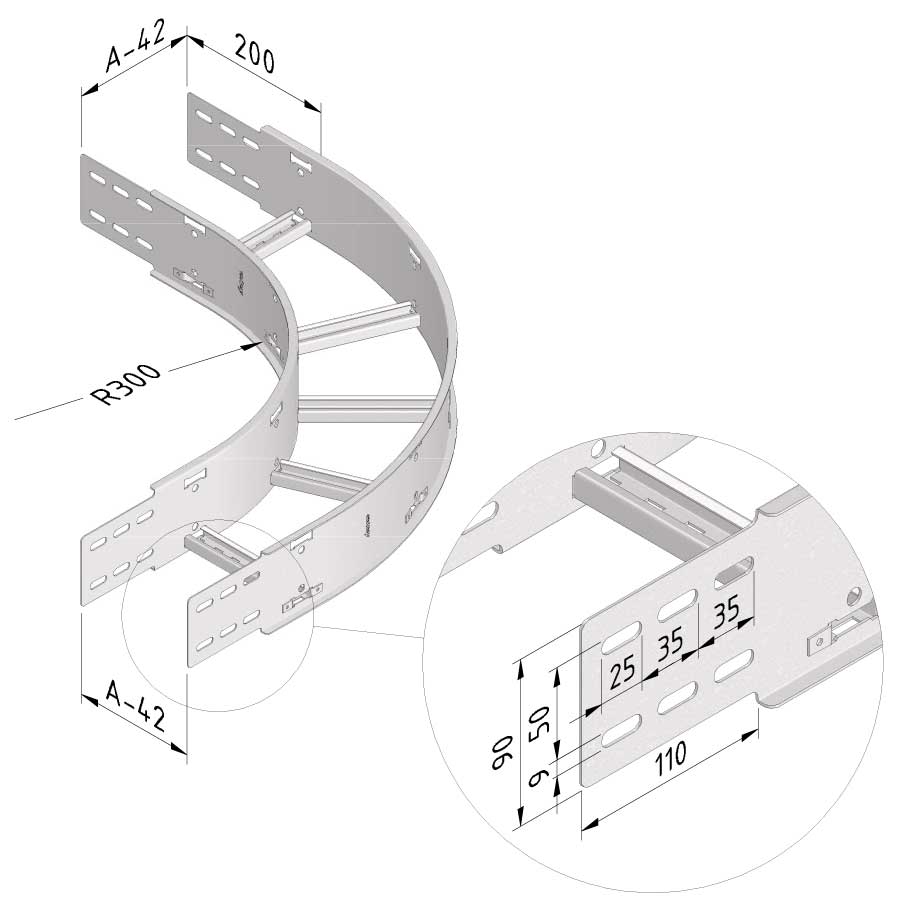

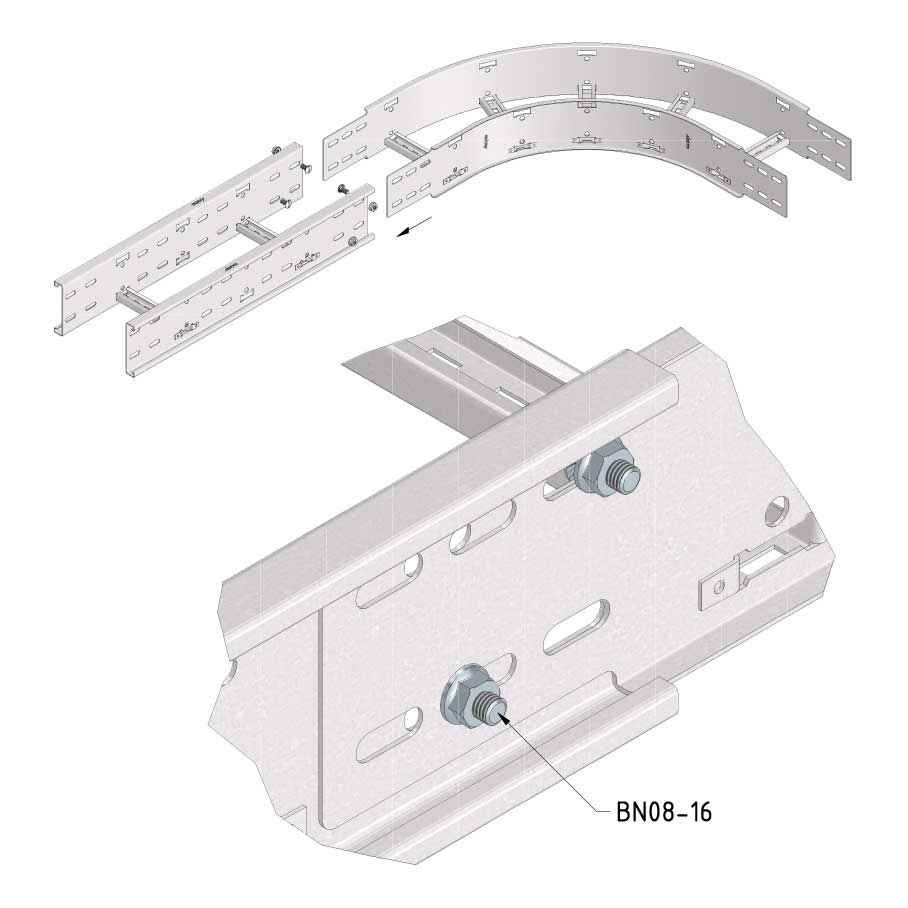

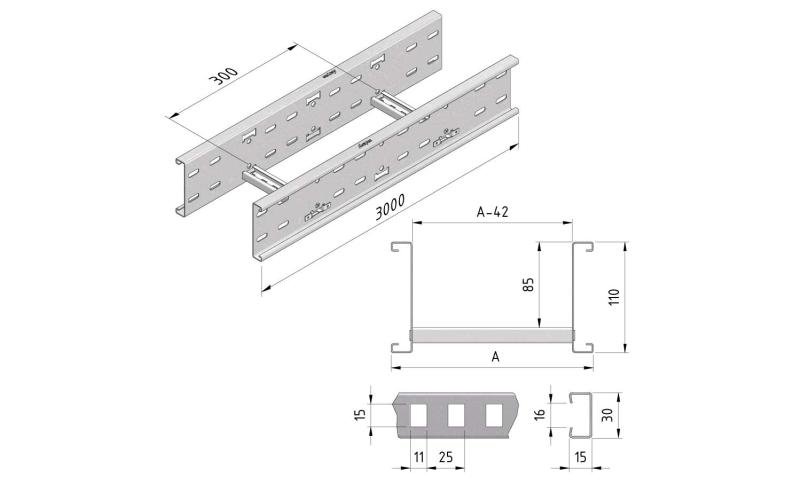

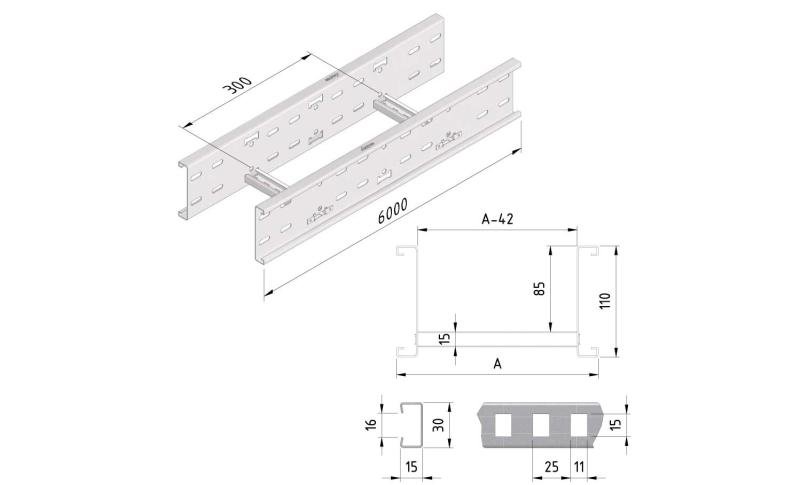

Bend CLF110

CLF110-B90

Bend CLF110

CLF110-B90

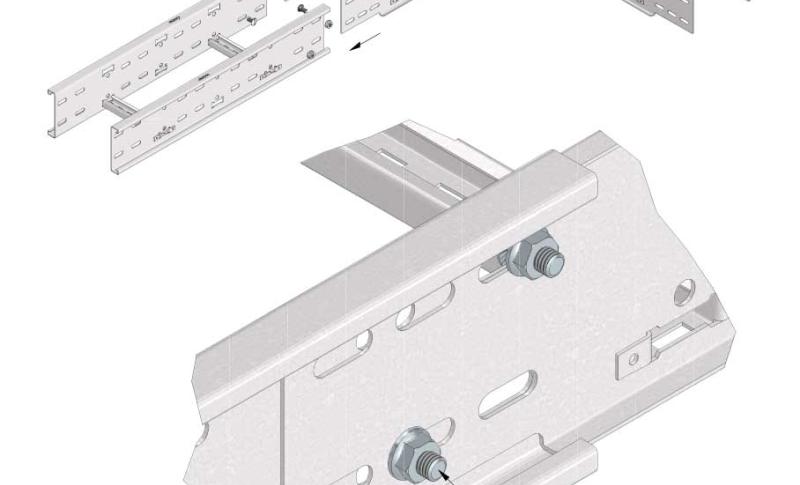

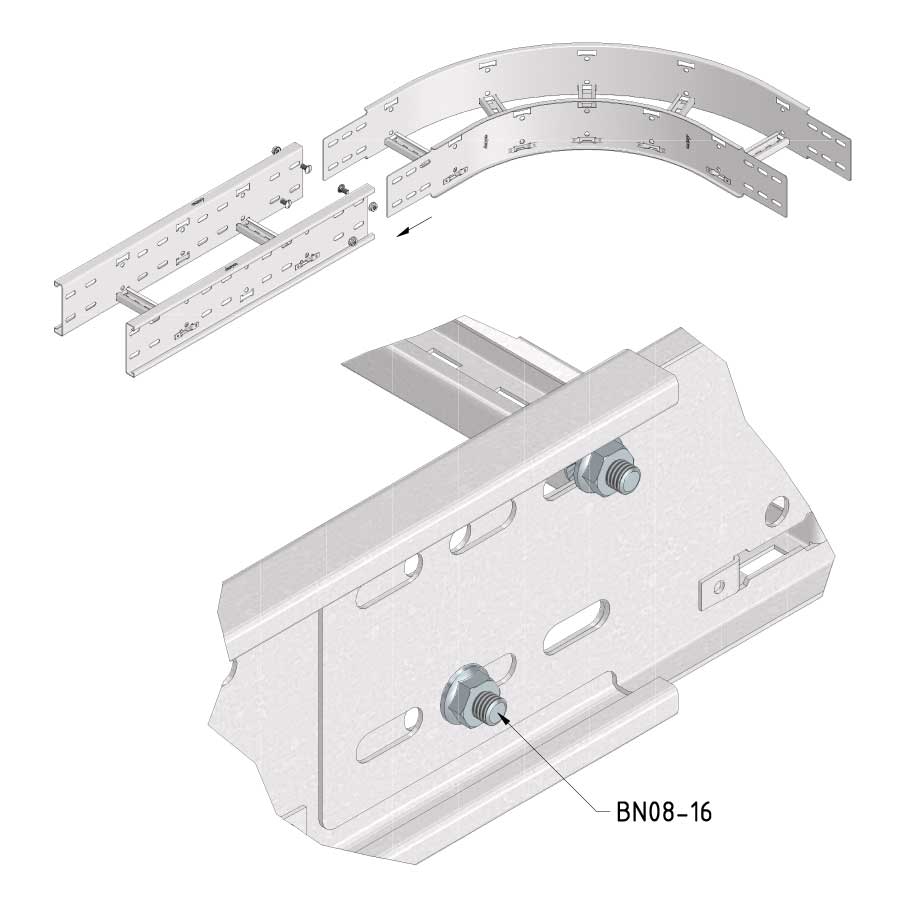

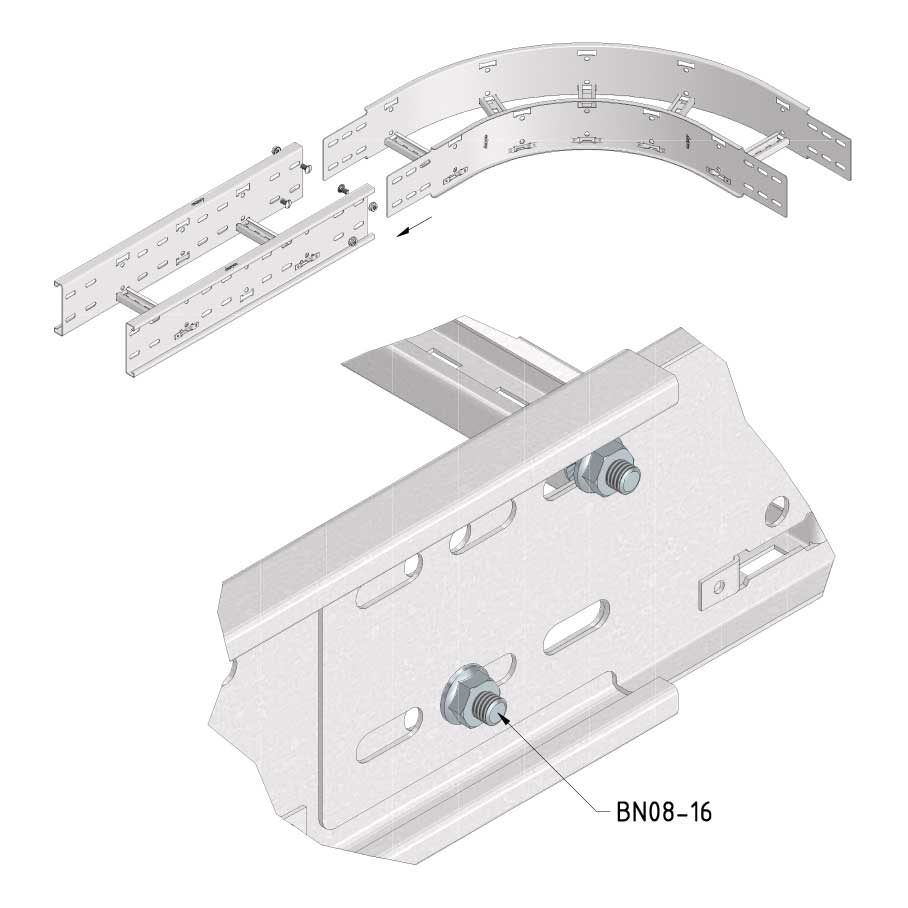

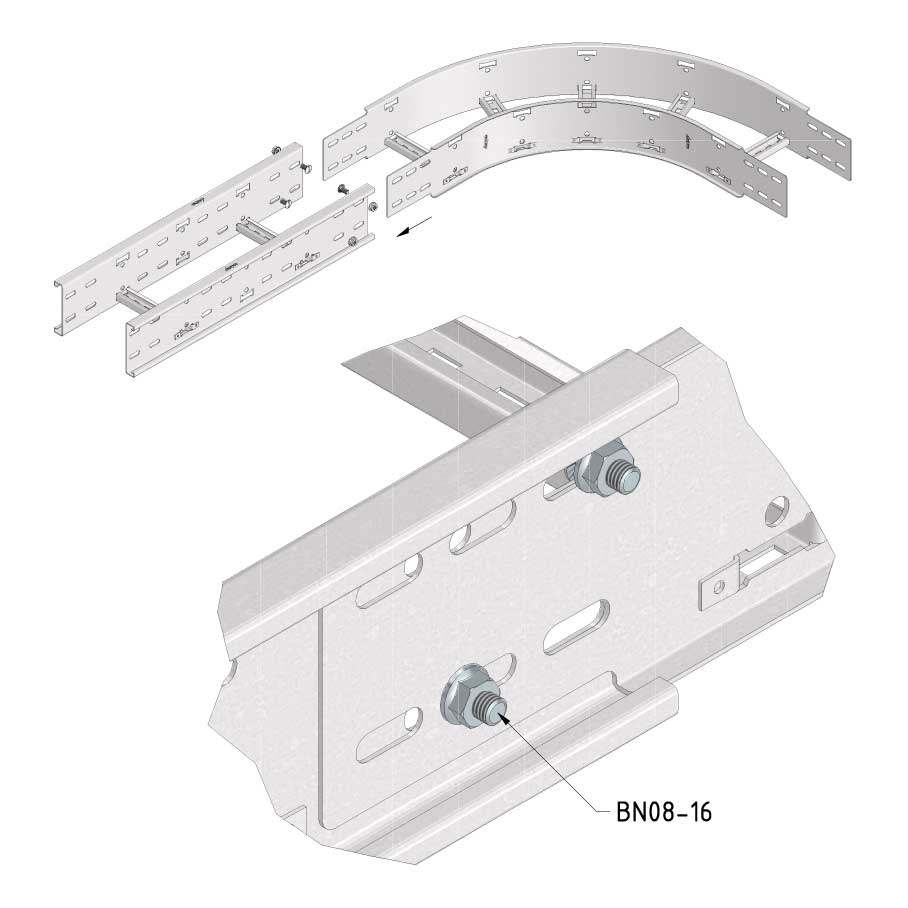

Connect with BN08-16

Coated finishing available on demand. RAL colour code to be confirmed on your order

| SKU | Article code | Finishing | Dimension A | Packaging | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

18594 |

CLF110-B90-0200-UG |

UG

|

200

|

1

|

Default

|

|

||||

Workload

Additional information

Finishing

ULTRA GALVA (UG)

This a high-performant metallic coating which offers an optimum surface protection in a wide variety of agressive and demanding environments, indoor as well as outdoor. The unique alloy of small amounts of magnesium and/or aluminium in the zinc bath provides ULTRA protection with a self-healing effect. Whilst zinc is essential for cathodic protection, magnesium prevents red rust. The passivation layer that comes on top, creates a seal that slows down the first traces of white rust. ULTRA GALVA offers a number of advantages compared to the traditional hot dip finishing. - the passivation layer offers a superior protection level. Hence, ULTRA GALVA, being cathodical, is self-healing in case of scratches, edges or perforations. Compared to hot dip, the articles remain very straight, no deflections appear nor flux or dull spots/ashes - ULTRA GALVA can conveniently be cold-processed without any risk on flakes because of the perfect adhesion of the coating to the metal - no zinc pins appear which enables one to install cables in a fast way avoiding any risk on damages to cables nor injuries of workers - thanks to the longer life span, ULTRA GALVA does not require ongoing maintenance nor post painting actions - three times less zinc is being applied compared to hot dip finishing - there is hence a lower impact on natural ressources as well as less pollution -on top, its production process generates less CO2 emission and ULTRA GALVA is 100% recyclable. ULTRA GALVA is hence a vary valuable environmentally friendly alternative for the traditional stainless steel and hot-dip finishing! |

|||||||||||

|

|

18595 |

CLF110-B90-0300-UG |

UG

|

300

|

1

|

Default

|

|

||||

Workload

Additional information

Finishing

ULTRA GALVA (UG)

This a high-performant metallic coating which offers an optimum surface protection in a wide variety of agressive and demanding environments, indoor as well as outdoor. The unique alloy of small amounts of magnesium and/or aluminium in the zinc bath provides ULTRA protection with a self-healing effect. Whilst zinc is essential for cathodic protection, magnesium prevents red rust. The passivation layer that comes on top, creates a seal that slows down the first traces of white rust. ULTRA GALVA offers a number of advantages compared to the traditional hot dip finishing. - the passivation layer offers a superior protection level. Hence, ULTRA GALVA, being cathodical, is self-healing in case of scratches, edges or perforations. Compared to hot dip, the articles remain very straight, no deflections appear nor flux or dull spots/ashes - ULTRA GALVA can conveniently be cold-processed without any risk on flakes because of the perfect adhesion of the coating to the metal - no zinc pins appear which enables one to install cables in a fast way avoiding any risk on damages to cables nor injuries of workers - thanks to the longer life span, ULTRA GALVA does not require ongoing maintenance nor post painting actions - three times less zinc is being applied compared to hot dip finishing - there is hence a lower impact on natural ressources as well as less pollution -on top, its production process generates less CO2 emission and ULTRA GALVA is 100% recyclable. ULTRA GALVA is hence a vary valuable environmentally friendly alternative for the traditional stainless steel and hot-dip finishing! |

|||||||||||

|

|

18596 |

CLF110-B90-0400-UG |

UG

|

400

|

1

|

Default

|

|

||||

Workload

Additional information

Finishing

ULTRA GALVA (UG)

This a high-performant metallic coating which offers an optimum surface protection in a wide variety of agressive and demanding environments, indoor as well as outdoor. The unique alloy of small amounts of magnesium and/or aluminium in the zinc bath provides ULTRA protection with a self-healing effect. Whilst zinc is essential for cathodic protection, magnesium prevents red rust. The passivation layer that comes on top, creates a seal that slows down the first traces of white rust. ULTRA GALVA offers a number of advantages compared to the traditional hot dip finishing. - the passivation layer offers a superior protection level. Hence, ULTRA GALVA, being cathodical, is self-healing in case of scratches, edges or perforations. Compared to hot dip, the articles remain very straight, no deflections appear nor flux or dull spots/ashes - ULTRA GALVA can conveniently be cold-processed without any risk on flakes because of the perfect adhesion of the coating to the metal - no zinc pins appear which enables one to install cables in a fast way avoiding any risk on damages to cables nor injuries of workers - thanks to the longer life span, ULTRA GALVA does not require ongoing maintenance nor post painting actions - three times less zinc is being applied compared to hot dip finishing - there is hence a lower impact on natural ressources as well as less pollution -on top, its production process generates less CO2 emission and ULTRA GALVA is 100% recyclable. ULTRA GALVA is hence a vary valuable environmentally friendly alternative for the traditional stainless steel and hot-dip finishing! |

|||||||||||

|

|

18597 |

CLF110-B90-0500-UG |

UG

|

500

|

1

|

Default

|

|

||||

Workload

Additional information

Finishing

ULTRA GALVA (UG)

This a high-performant metallic coating which offers an optimum surface protection in a wide variety of agressive and demanding environments, indoor as well as outdoor. The unique alloy of small amounts of magnesium and/or aluminium in the zinc bath provides ULTRA protection with a self-healing effect. Whilst zinc is essential for cathodic protection, magnesium prevents red rust. The passivation layer that comes on top, creates a seal that slows down the first traces of white rust. ULTRA GALVA offers a number of advantages compared to the traditional hot dip finishing. - the passivation layer offers a superior protection level. Hence, ULTRA GALVA, being cathodical, is self-healing in case of scratches, edges or perforations. Compared to hot dip, the articles remain very straight, no deflections appear nor flux or dull spots/ashes - ULTRA GALVA can conveniently be cold-processed without any risk on flakes because of the perfect adhesion of the coating to the metal - no zinc pins appear which enables one to install cables in a fast way avoiding any risk on damages to cables nor injuries of workers - thanks to the longer life span, ULTRA GALVA does not require ongoing maintenance nor post painting actions - three times less zinc is being applied compared to hot dip finishing - there is hence a lower impact on natural ressources as well as less pollution -on top, its production process generates less CO2 emission and ULTRA GALVA is 100% recyclable. ULTRA GALVA is hence a vary valuable environmentally friendly alternative for the traditional stainless steel and hot-dip finishing! |

|||||||||||

|

|

18598 |

CLF110-B90-0600-UG |

UG

|

600

|

1

|

Default

|

|

||||

Workload

Additional information

Finishing

ULTRA GALVA (UG)

This a high-performant metallic coating which offers an optimum surface protection in a wide variety of agressive and demanding environments, indoor as well as outdoor. The unique alloy of small amounts of magnesium and/or aluminium in the zinc bath provides ULTRA protection with a self-healing effect. Whilst zinc is essential for cathodic protection, magnesium prevents red rust. The passivation layer that comes on top, creates a seal that slows down the first traces of white rust. ULTRA GALVA offers a number of advantages compared to the traditional hot dip finishing. - the passivation layer offers a superior protection level. Hence, ULTRA GALVA, being cathodical, is self-healing in case of scratches, edges or perforations. Compared to hot dip, the articles remain very straight, no deflections appear nor flux or dull spots/ashes - ULTRA GALVA can conveniently be cold-processed without any risk on flakes because of the perfect adhesion of the coating to the metal - no zinc pins appear which enables one to install cables in a fast way avoiding any risk on damages to cables nor injuries of workers - thanks to the longer life span, ULTRA GALVA does not require ongoing maintenance nor post painting actions - three times less zinc is being applied compared to hot dip finishing - there is hence a lower impact on natural ressources as well as less pollution -on top, its production process generates less CO2 emission and ULTRA GALVA is 100% recyclable. ULTRA GALVA is hence a vary valuable environmentally friendly alternative for the traditional stainless steel and hot-dip finishing! |

|||||||||||

No results

No results were found for your current search